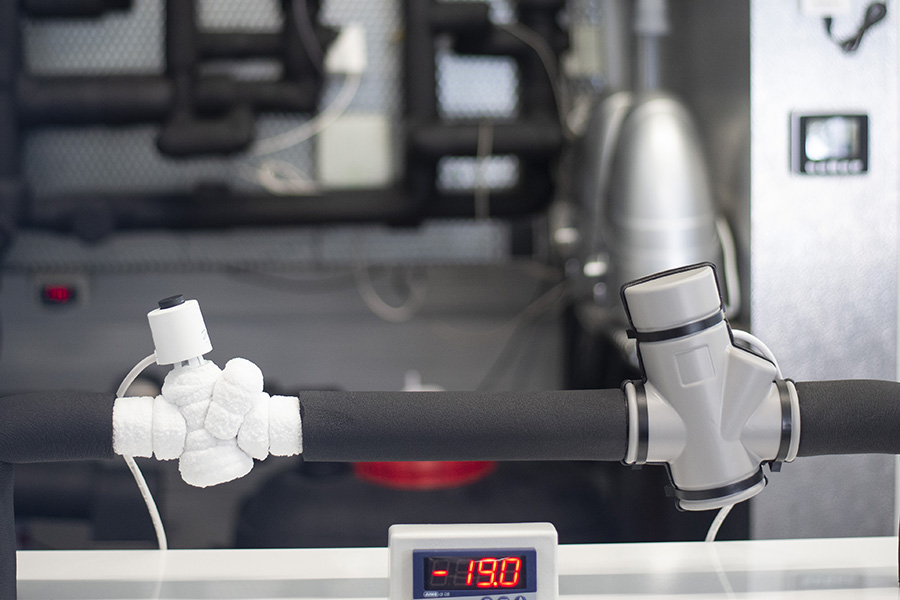

Test system for cold insulation

Materials research for refrigeration applications

We spent many years developing and testing before applying for a patent for removable and reusable cold insulation in 2012. Insulation for cold applications must function under all circumstances.

If thermal insulation allows some air to pass through or has a non-sealing spindle opening, then it is not quite as effective. However, this does not cause any damage to the fitting. The situation is different in cold areas: cold bridges lead to ice formation and ice tends to grow further and further. At some point the insulation will be “blown off”.

For this reason, we work with you beforehand to determine the maximum conditions to which the insulation will be exposed:

- Temperature of the medium flowing through

- Ambient temperature

- Air humidity

- Air movement

We design the insulation on the basis of the templates and then attach great importance to testing it under the specified conditions. This is the only way we can ensure that the closing mechanism seals and that the wall thickness is sufficiently designed. With our test system we can simulate the above 4 parameters.

We also gain important insights from the test facility when it comes to the subject of “skinning” and “coatings”. For some time now, we have been testing various materials that are suitable for use in the cold.