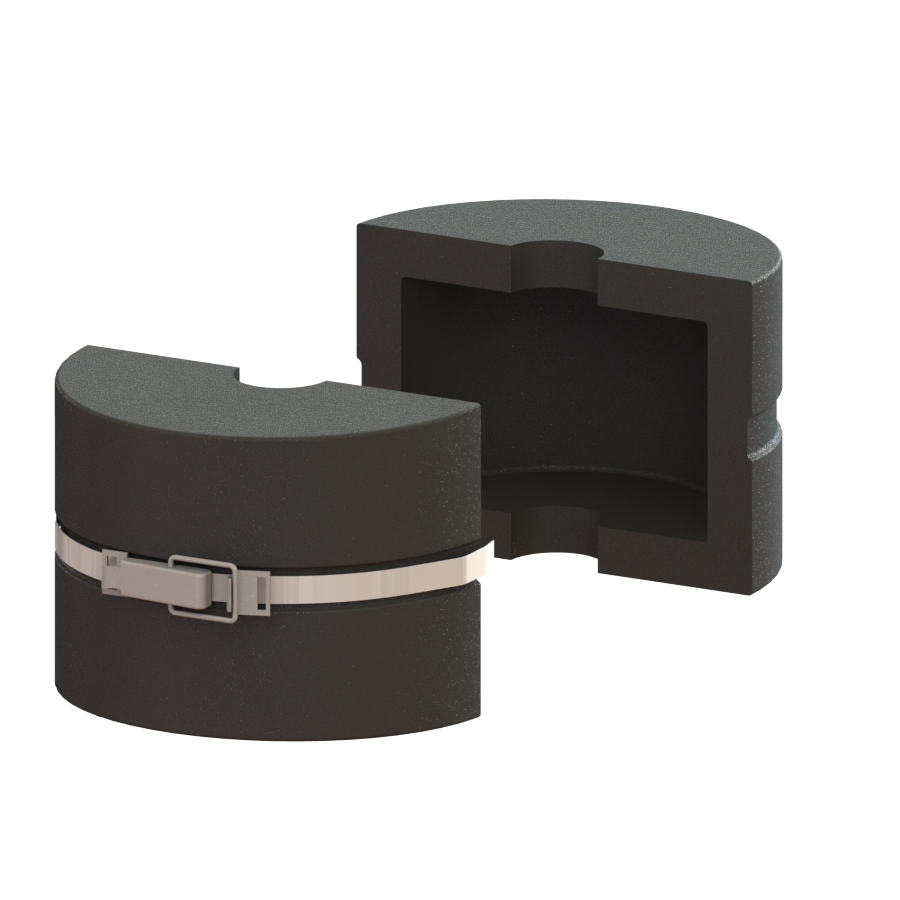

Stations consist of many components such as pipes, elbows, fittings such as ball valves and control valves, pumps and many more. Our DH system has been specially developed for this variety of shapes. The range comprises 6 shapes each for the socket and flange area as well as pipes and bends in nominal widths DN15 to DN125.

The material of the DH system is uncoated black rigid polyurethane foam, which can be used at temperatures of up to +130°C. At higher temperatures, you should use a more highly cross-linked polyisocyanurate rigid foam, which is available via the AL system.

The sheathed insulation makes installation and adaptation to the station components very easy. The material is easy to saw, drill and carve. Pipe passages, spindle openings, pipe outlets and drains are quickly made. We recommend insulating the fittings of the station first, then the bends and finally the open pipe sections.

Our technicians will be happy to answer any questions you may have. We also organize workshops for processing this system. If you are interested, please get in touch with our sales contacts.

For shut-off valves and globe valves in long face-to-face length (F1) with flange connection. Available in nominal sizes DN15 to DN125.

For angle seat valves and strainers with flange connection. Available in nominal sizes DN15 to DN125.

For globe valves in compact length F4 with flange connection. Available in nominal sizes DN15 to DN125.

For butterfly valves and KSB Boa Supercompact with flange connection. Available in nominal sizes DN15 to DN125.

For blind flanges and flange pairs. Available in nominal sizes DN15 to DN125.

For three-way mixers and valves with flange connection. Available in nominal sizes DN15 to DN125.

For globe valves and ball valves with T-handle and socket connection. Available in nominal sizes DN15 to DN80. Two nominal widths are combined in one mold. For the larger nominal width, the internal ribs are cut out.

For ball valves with short or flat stem and socket connection. Available in nominal sizes DN15 to DN80. Two nominal widths are combined in one mold. For the larger nominal width, the internal ribs are cut out.

For ball valves with short or flat stem and socket connection. Available in nominal sizes DN15 to DN80. Two nominal widths are combined in one mold. For the larger nominal width, the internal ribs are cut out.

For three-way mixers and valves with socket connection. Available in nominal sizes DN15 to DN50. Two nominal widths are combined in one mold. For the larger nominal width, the internal ribs are cut out.

Special series for Kähler strainers. Available in nominal sizes DN20 to DN50. The nominal widths DN20 and DN25 are combined in one mold. With the larger nominal width, the internal ribs are cut out.

Special series for Högfors mud flaps. Available in nominal sizes DN15 to DN40. The nominal sizes 15 to 25 and 32 to 40 are each combined in one mold. For the larger nominal width, the internal ribs are cut out.

For pipes. The wall thickness corresponds to the 50% specification of the current EnEV. Available in nominal sizes DN15 to DN200. Up to DN80, two nominal widths are combined in one mold. For the larger nominal width, the internal ribs are cut out. The length of a pipe shell is 500mm in nominal sizes DN15 to DN125, 1,000mm in nominal sizes DN150 and DN200.

For pipes. The wall thickness corresponds to the 100% specification of the current EnEV. Available in nominal sizes DN15 to DN80. Two nominal widths are combined in one mold. For the larger nominal width, the internal ribs are cut out. The length of a pipe shell is 500mm.

For pipe bends of type r1.5. The wall thickness corresponds to the 50% specification of the current EnEV. Available in nominal sizes DN15 to DN200. Up to DN80, two nominal widths are combined in one mold. For the larger nominal width, the internal ribs are cut out.

For pipe bends of type r1.5. The wall thickness corresponds to the 100% specification of the current EnEV. Available in nominal sizes DN15 to DN80. Two nominal widths are combined in one mold. For the larger nominal width, the internal ribs are cut out.

| Material | Rigid polyurethane foam |

| Spec. Volume weight | 55 – 60 kg/m³ |

| Color | black |

| Thermal conductivity | 0.022 W/mK at 10°C according to EN 12667 0.025 W/mK at 40°C according to EN 12667 0.029 W/mK at 10°C according to EN 14308 0.032 W/mK at 40°C according to EN 14308 |

| Application | Heat up to 130°C |

| Fire protection class | B2 according to DIN 4102 and E according to EN 13501-1 |