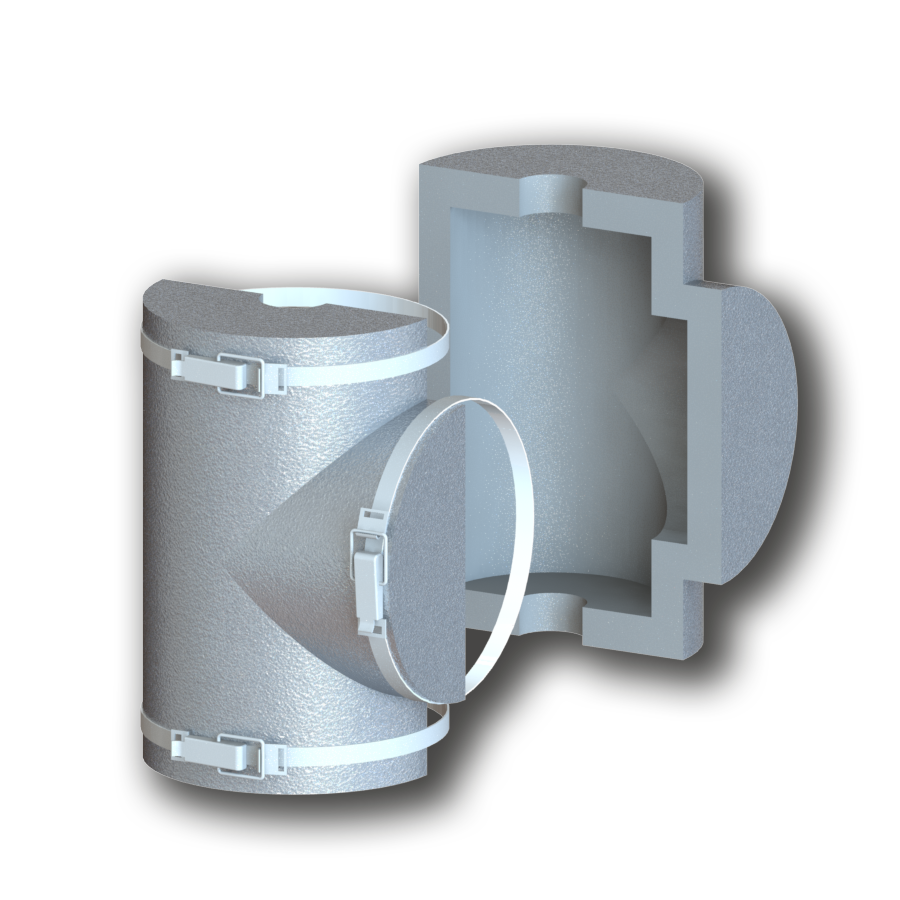

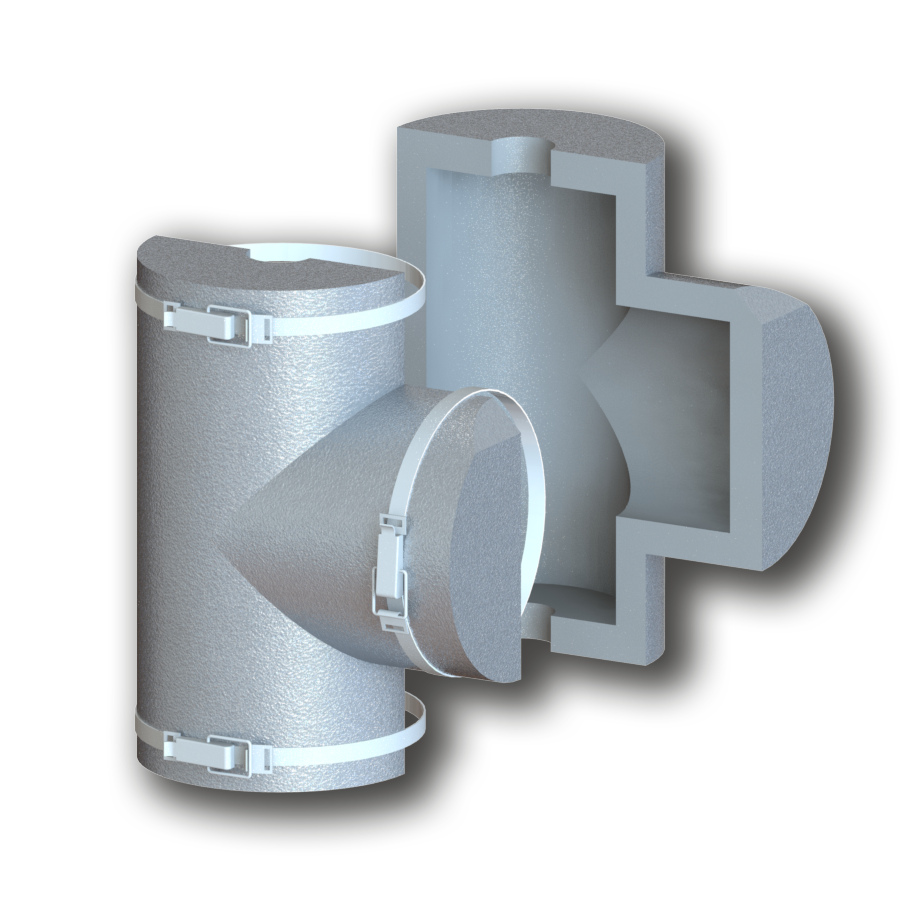

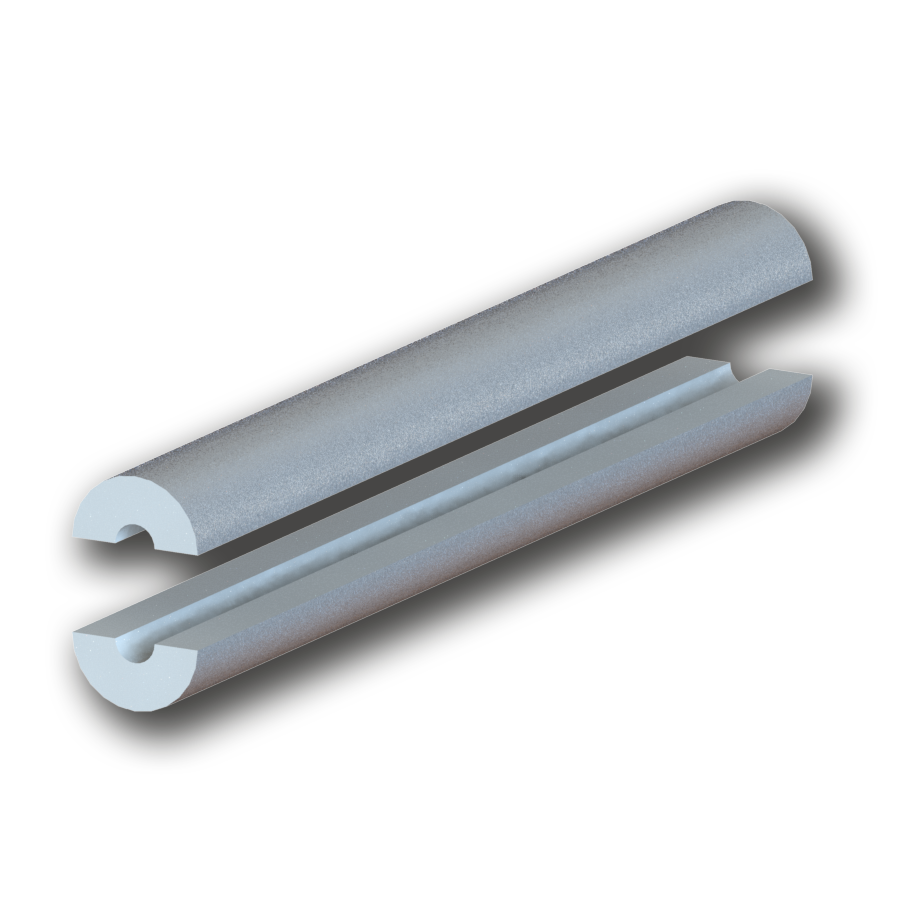

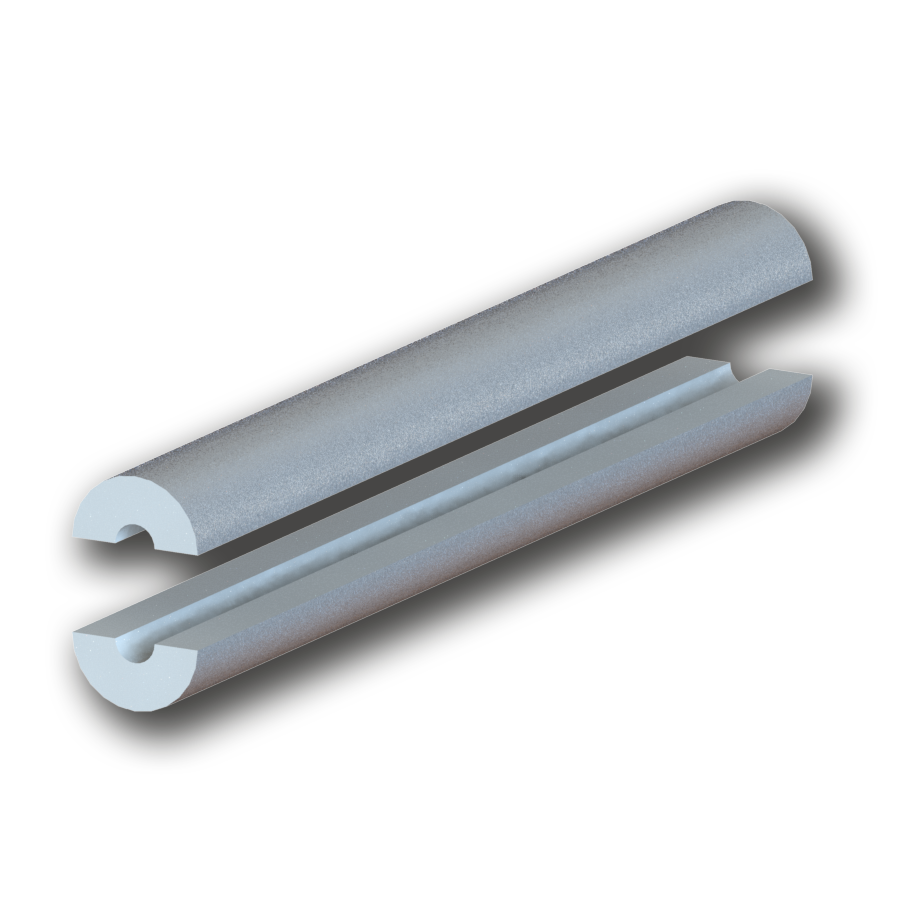

The AL system basically consists only of pipes and bends. The variety is due to the dimensioning of the pipes: the inner and outer diameters are precisely matched. You can therefore not only insulate individual pipe sections, but also cover the entire station “telescopically”. This “PIP (Pipe-in-Pipe) and POP (Pipe-over-Pipe)” concept has been patented by us. The instructions for this concept can be found under “Assembly”.

The range of applications for this system is very wide: the aluminum outer skin allows the system to be diffusion-tight and can therefore be used down to sub-zero temperatures. This system can be used at temperatures of up to +150°C, as we use a special, highly cross-linked polyisocyanurate rigid foam. At peak temperatures it can even reach +170°C.

Overview of the AL system:

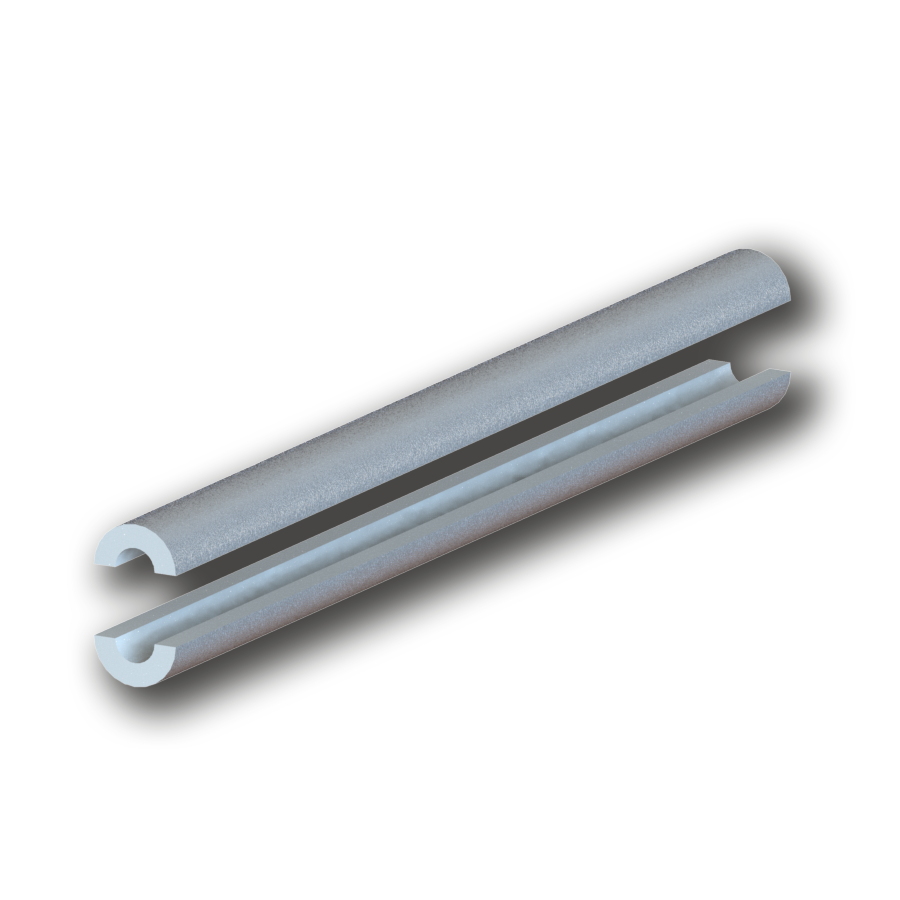

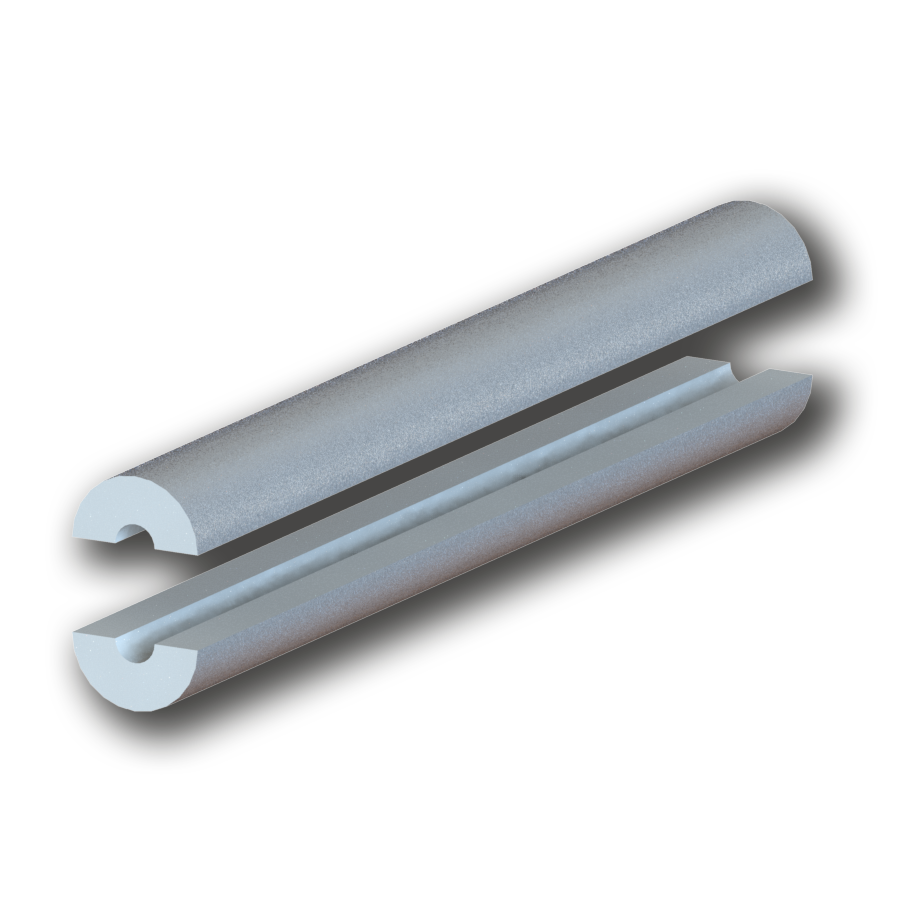

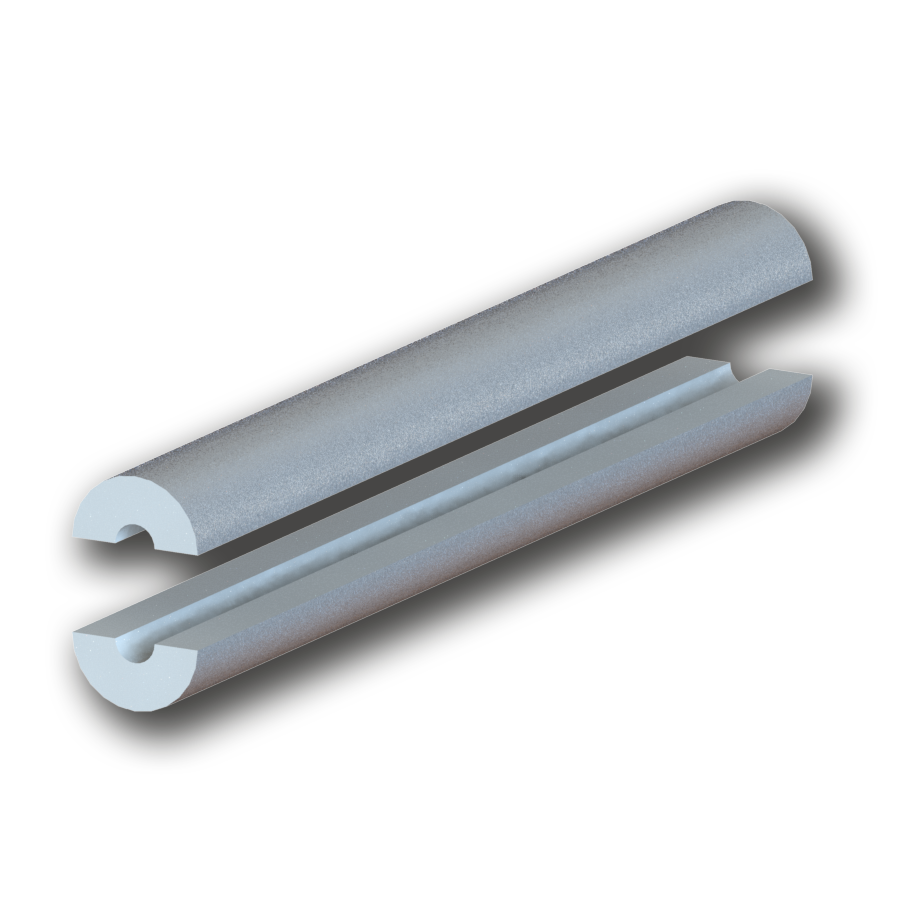

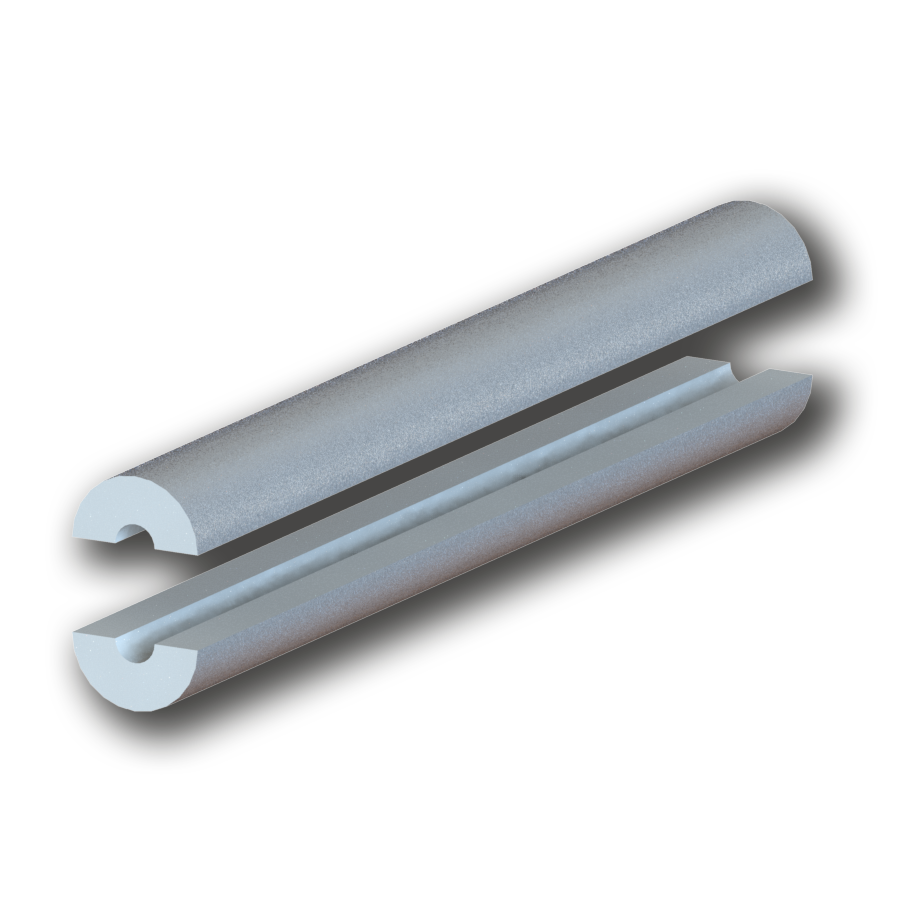

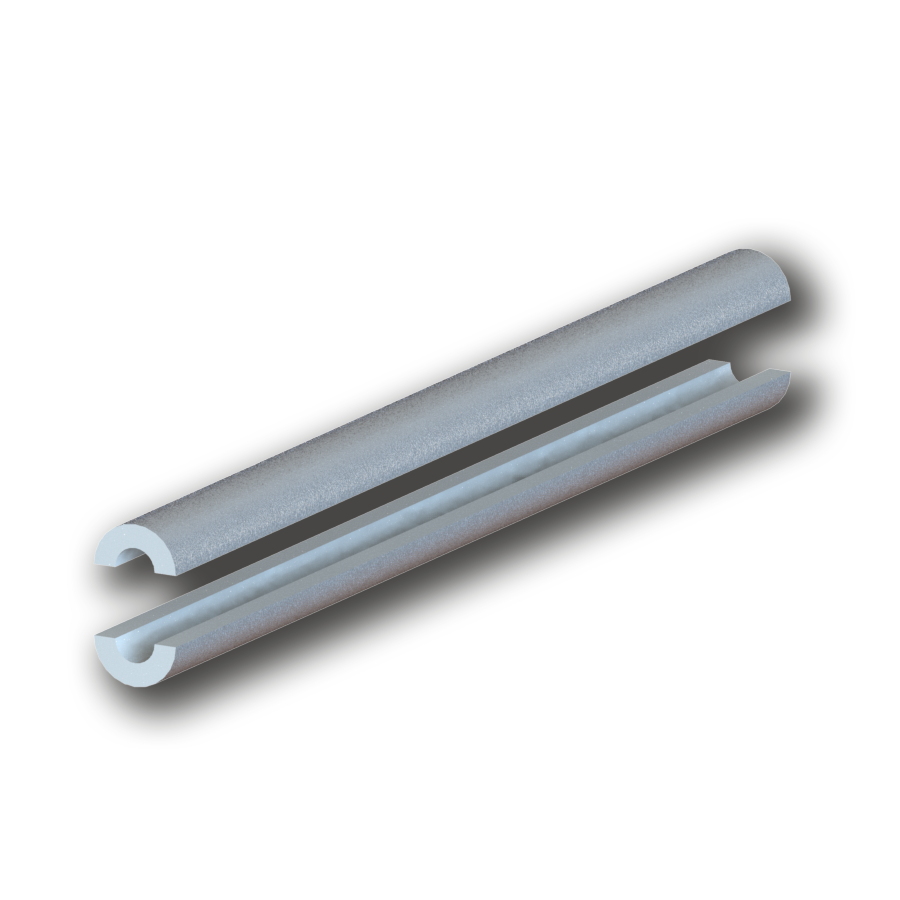

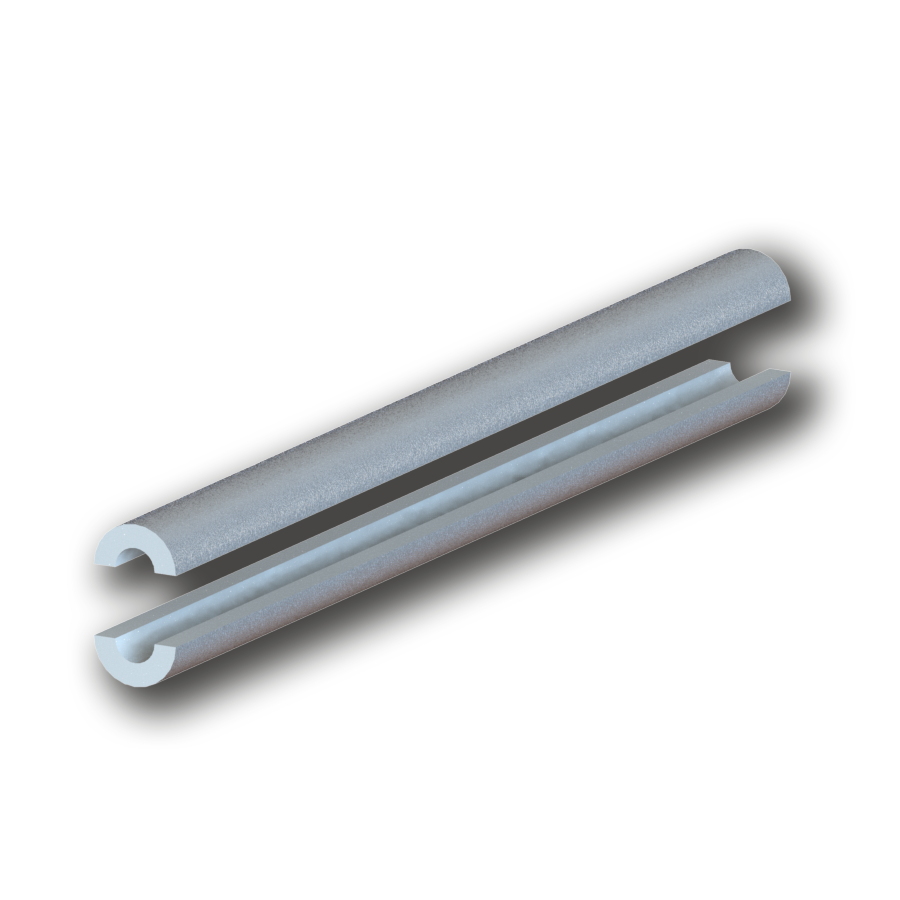

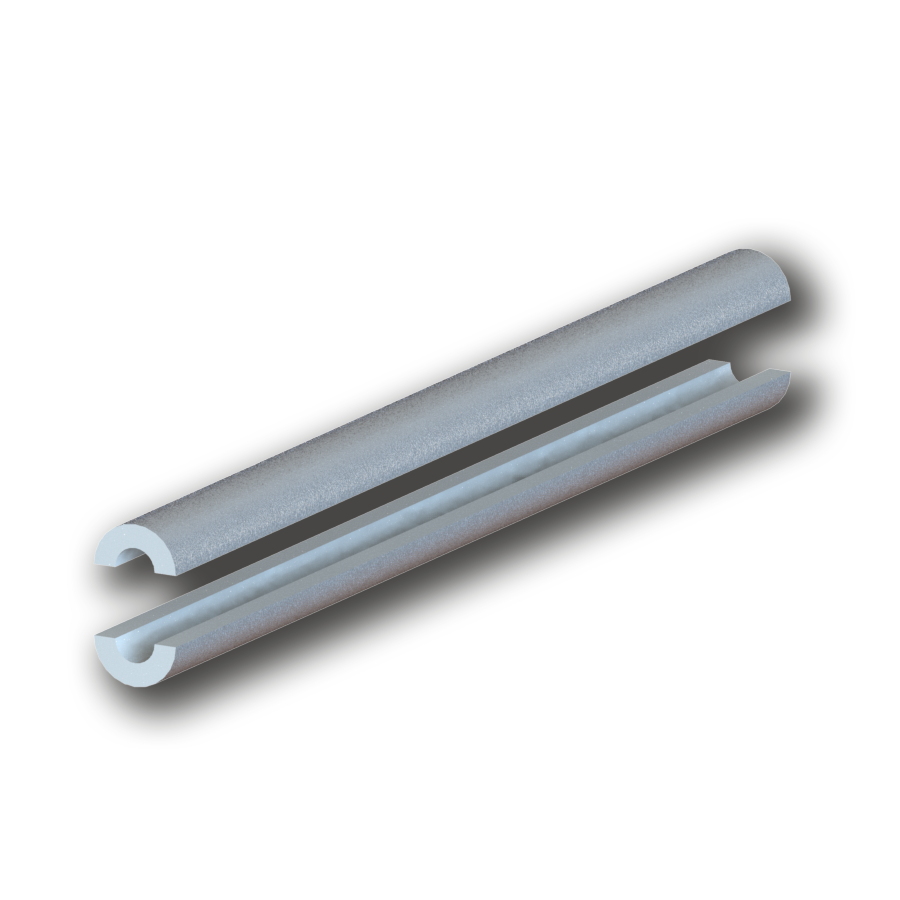

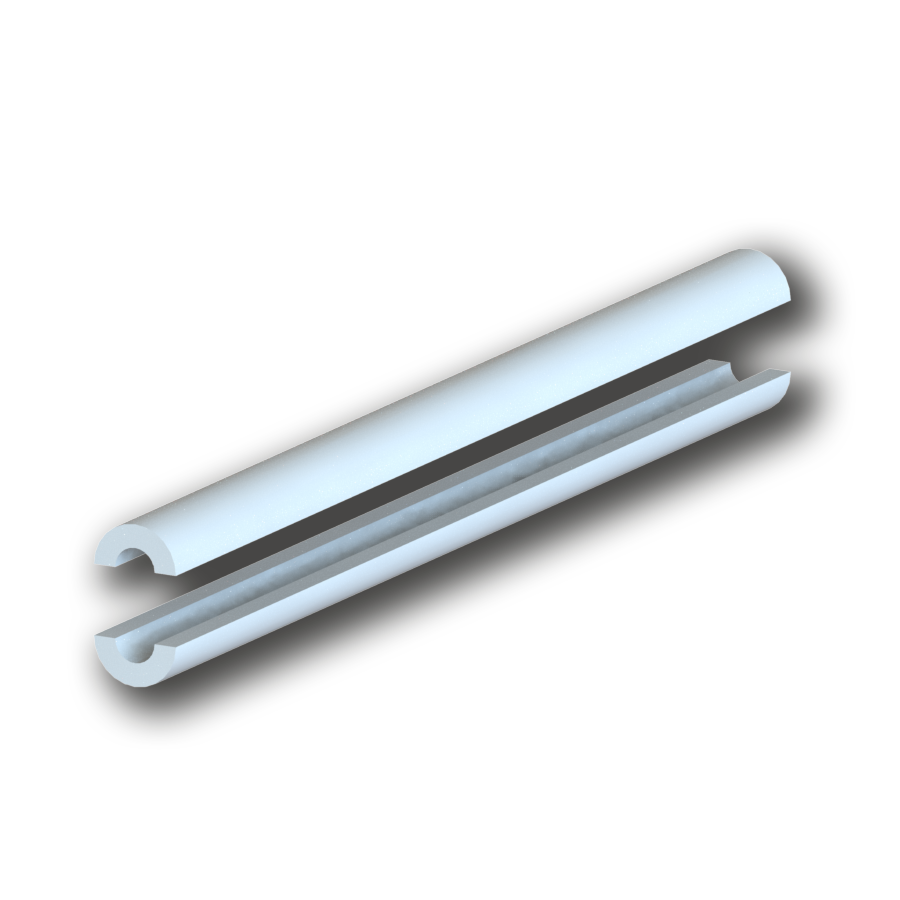

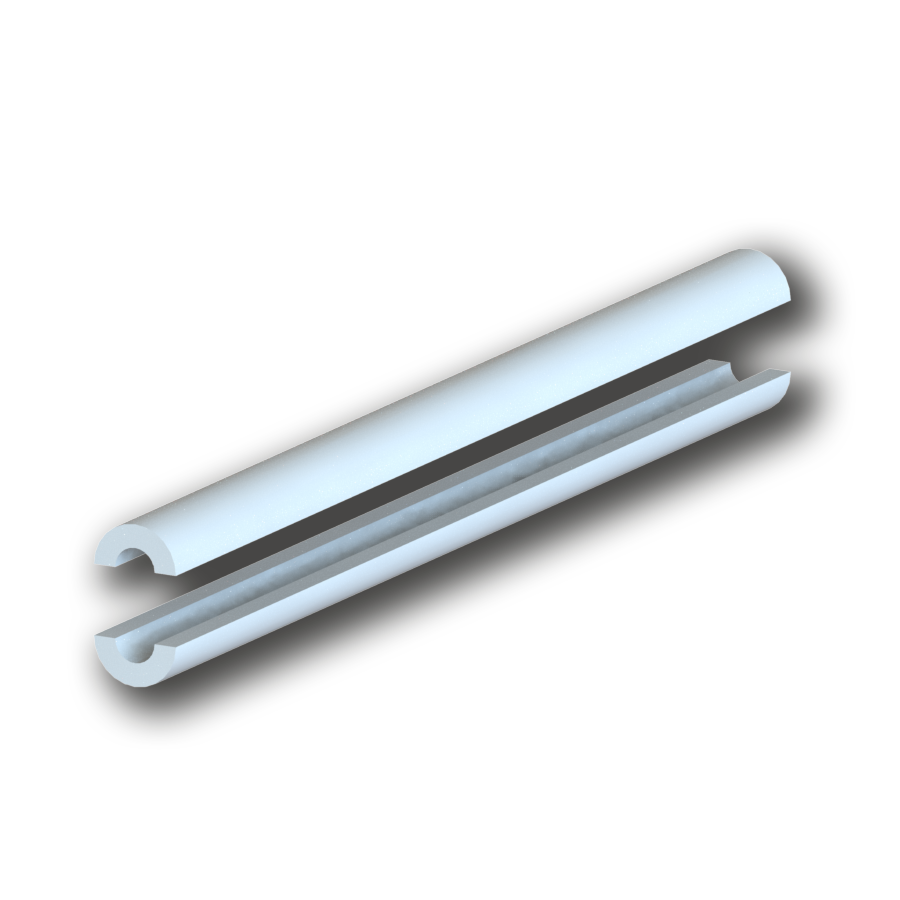

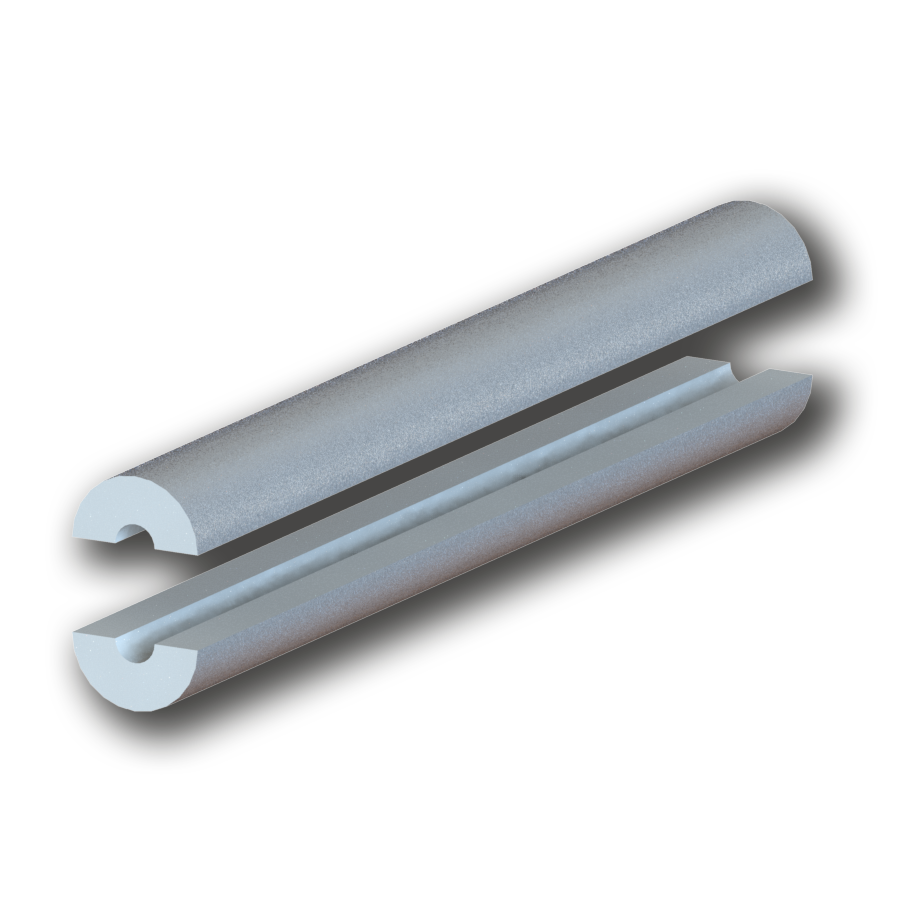

The AL system is based on round and square tube insulation. The variety results from the dimensioning and telescoping of the tubes.

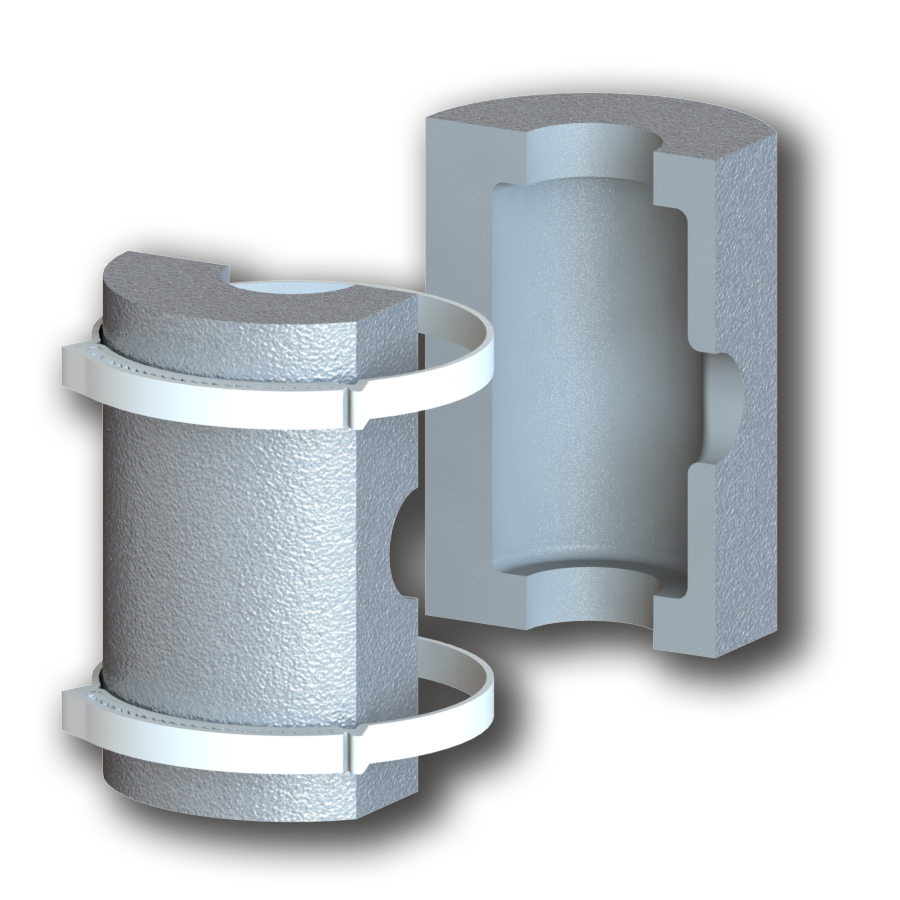

For straight seat fittings with flange connection.

For straight seat fittings with flange connection.

For butterfly valves with flange connection.

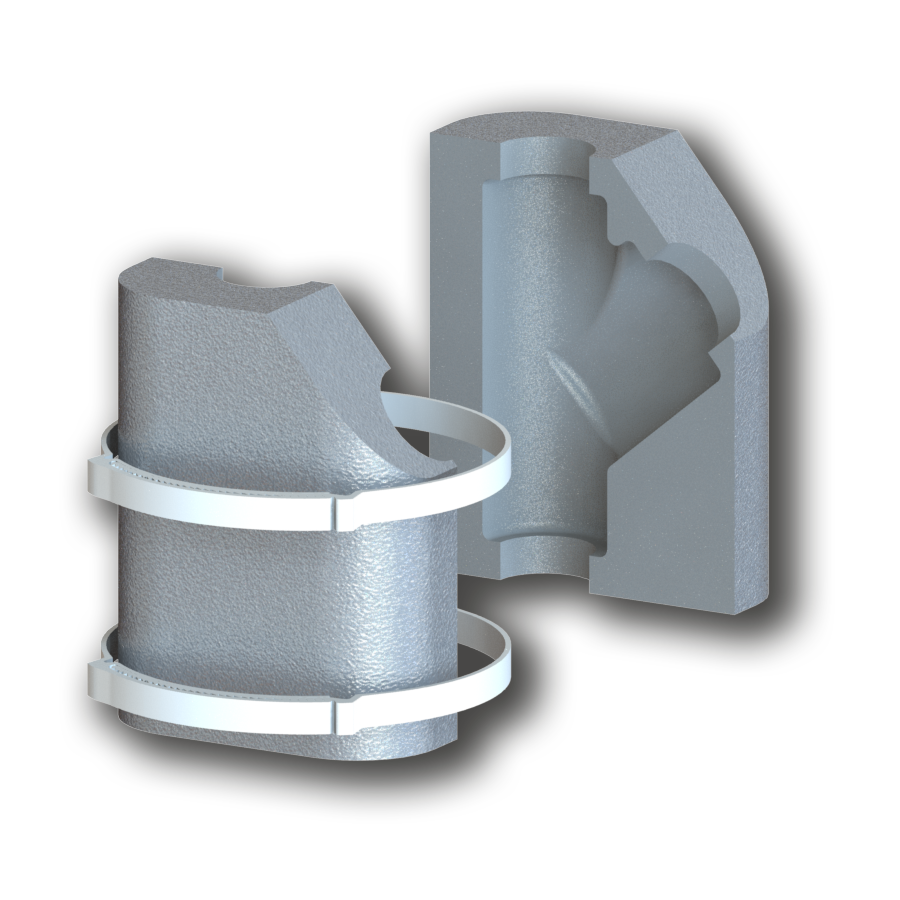

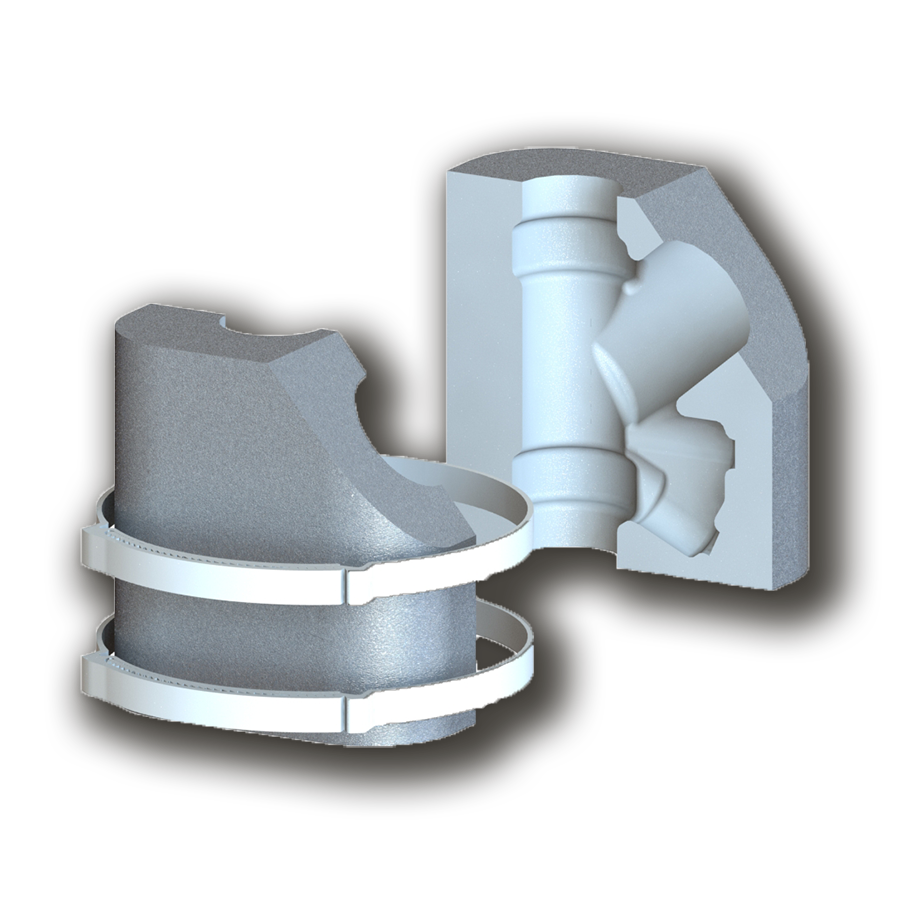

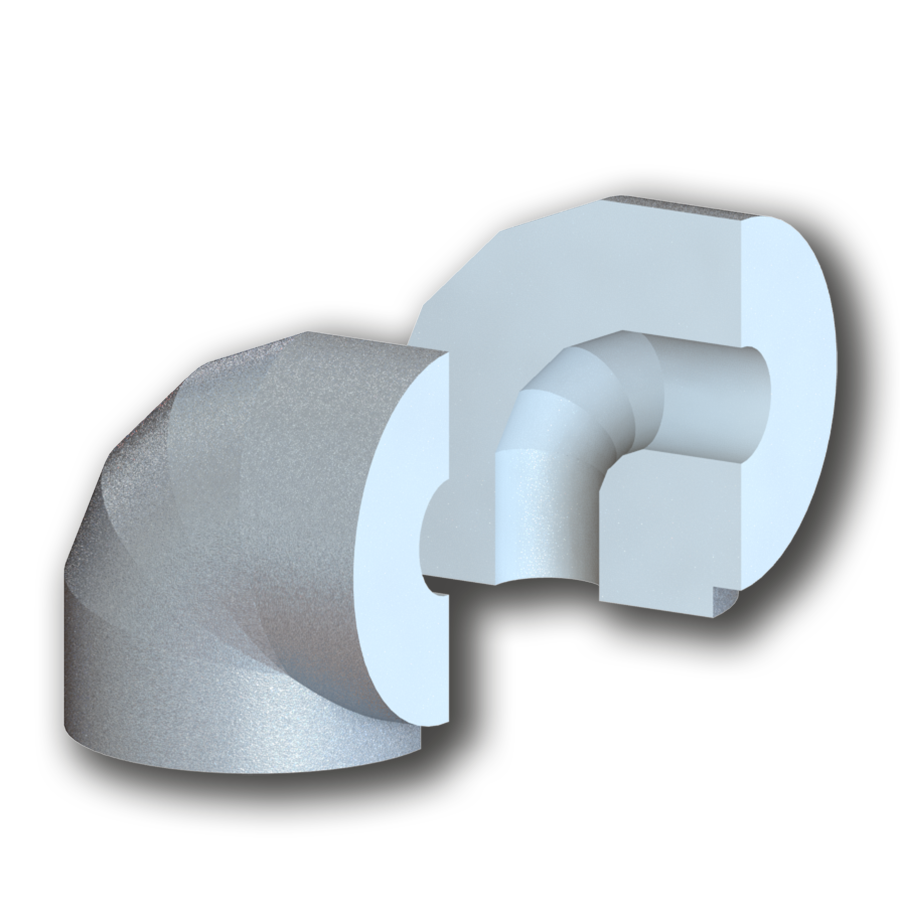

For angle seat fittings with flange connection.

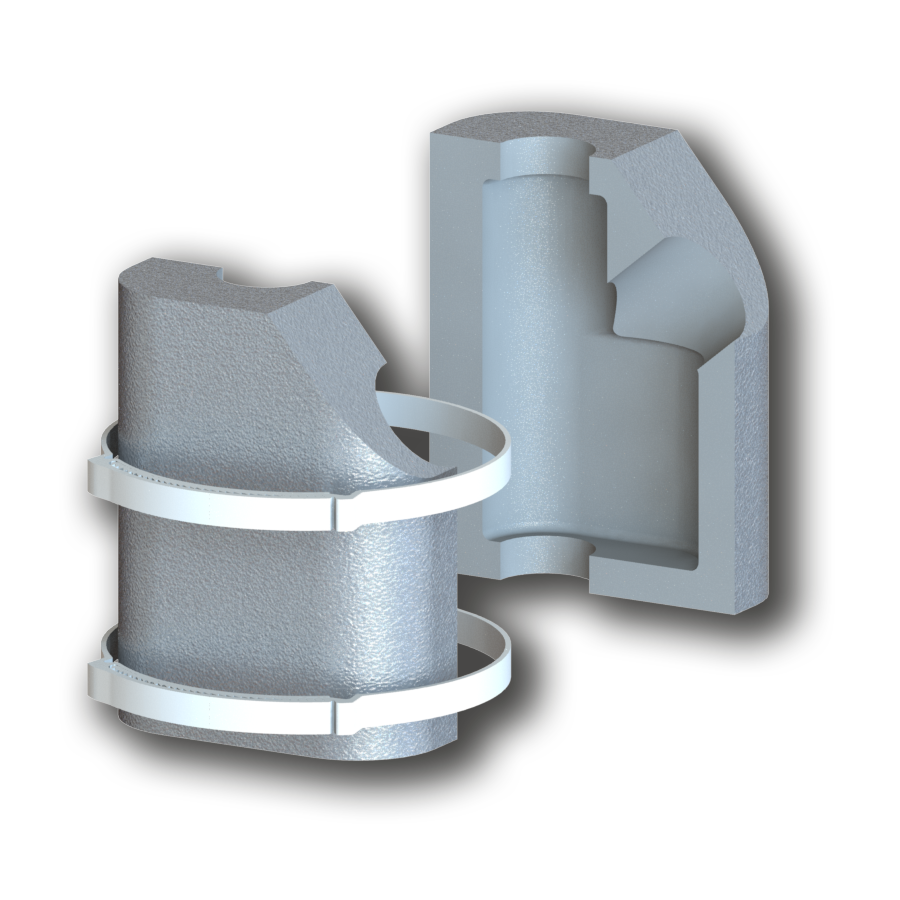

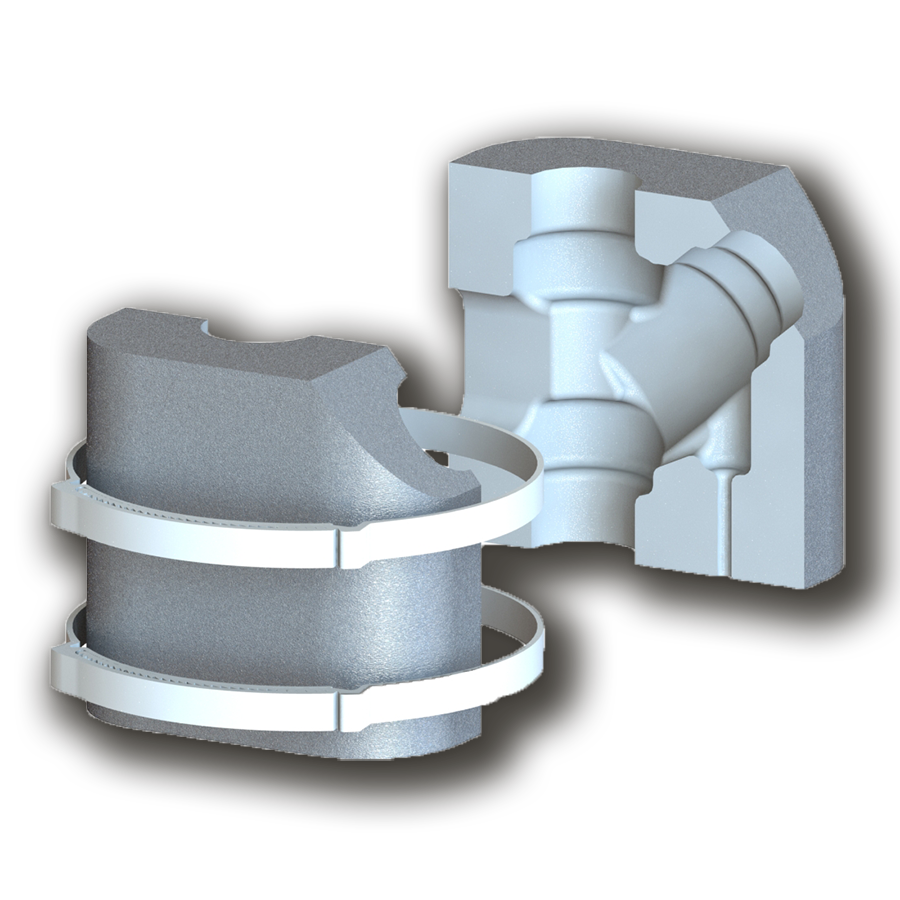

For strainers with flange connection.

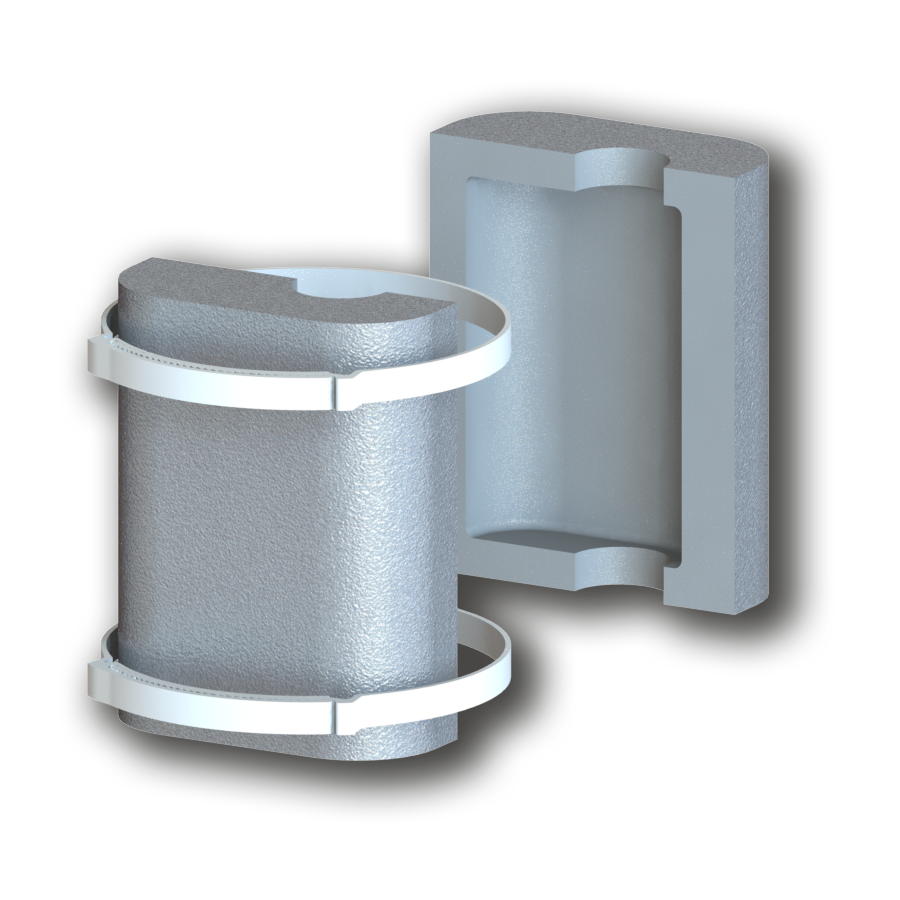

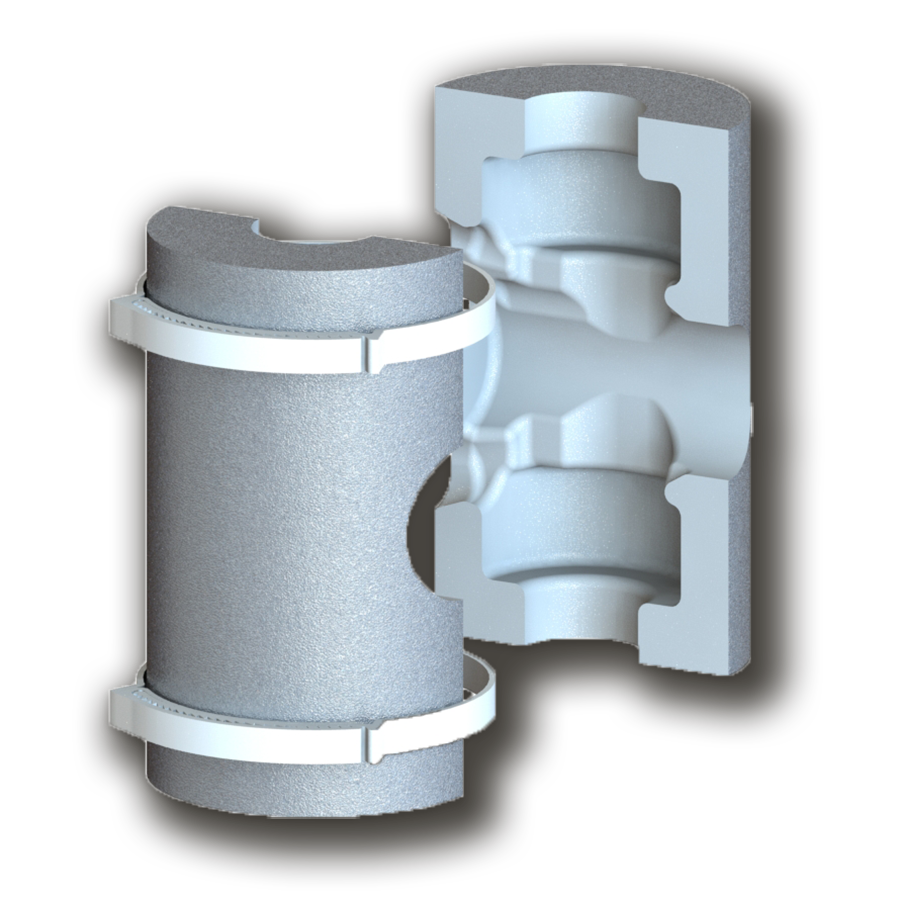

For ball valves with flange connection.

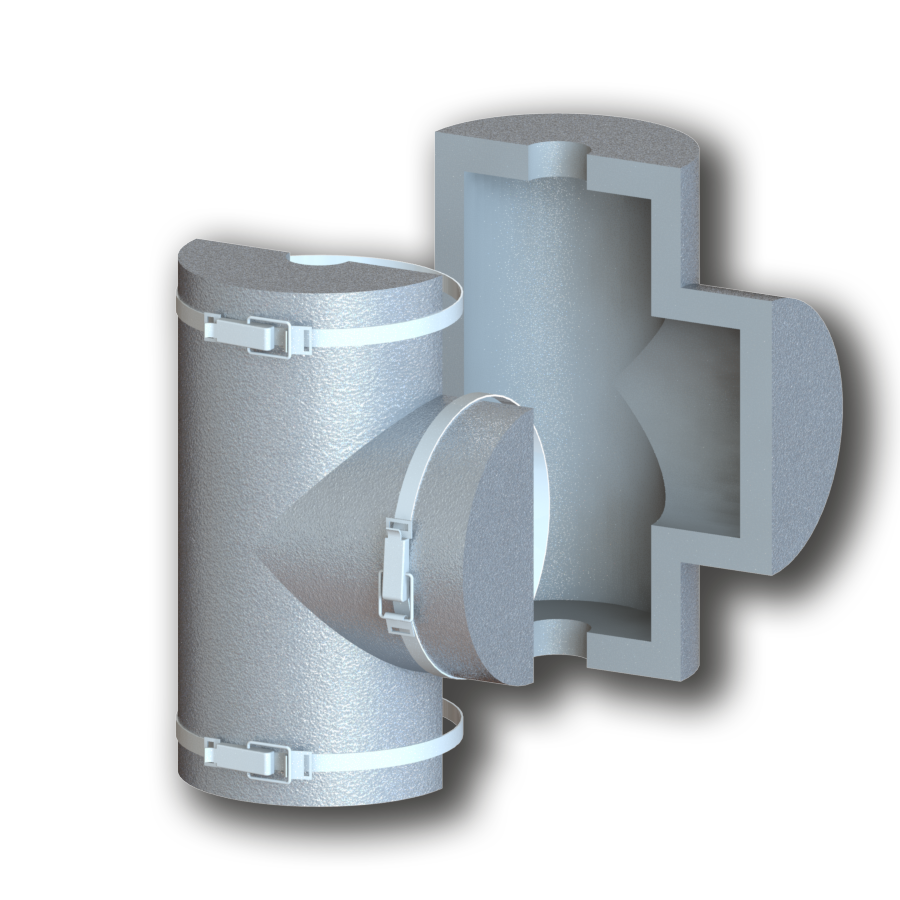

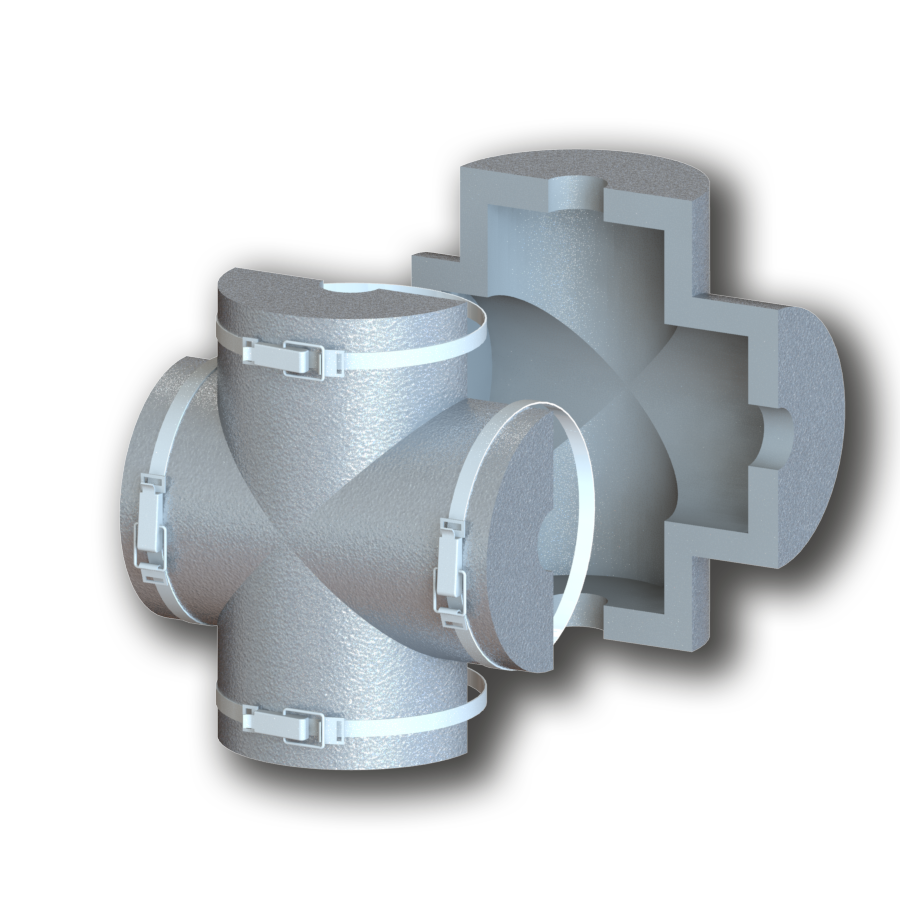

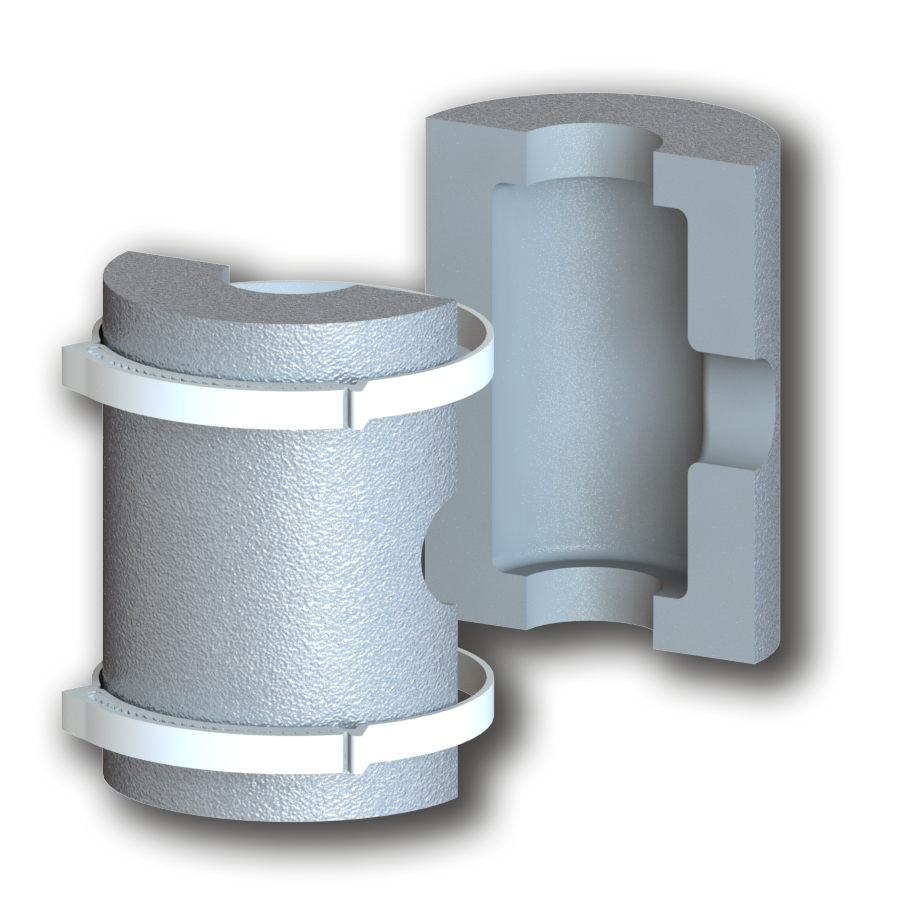

For three-way valves with flange connection.

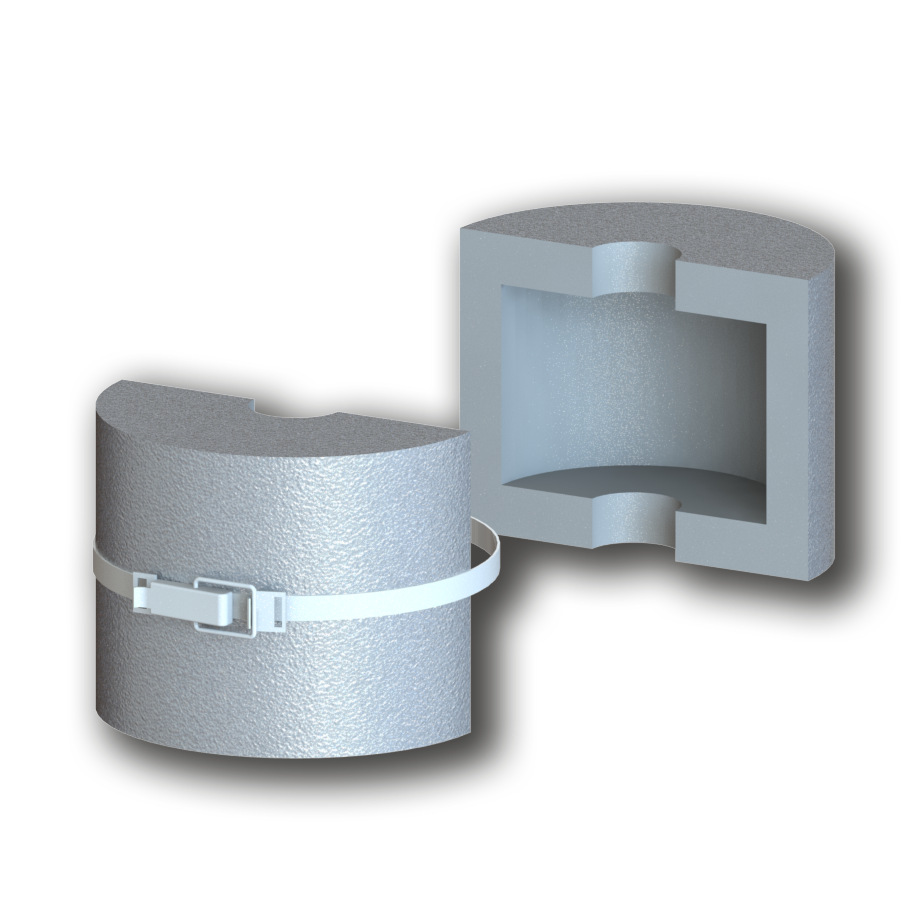

For flange pairs and blind flanges.

For angle seat valves with threaded connection.

For angle seat valves with frontal draining and threaded connection.

For strainers with socket connection.

For ball valves with threaded connection.

For ball valves with short spindle with threaded connection.

For KSB BOA-Control SBV

For KSB BOA-Control PIC

For KSB BOA-Control DPR

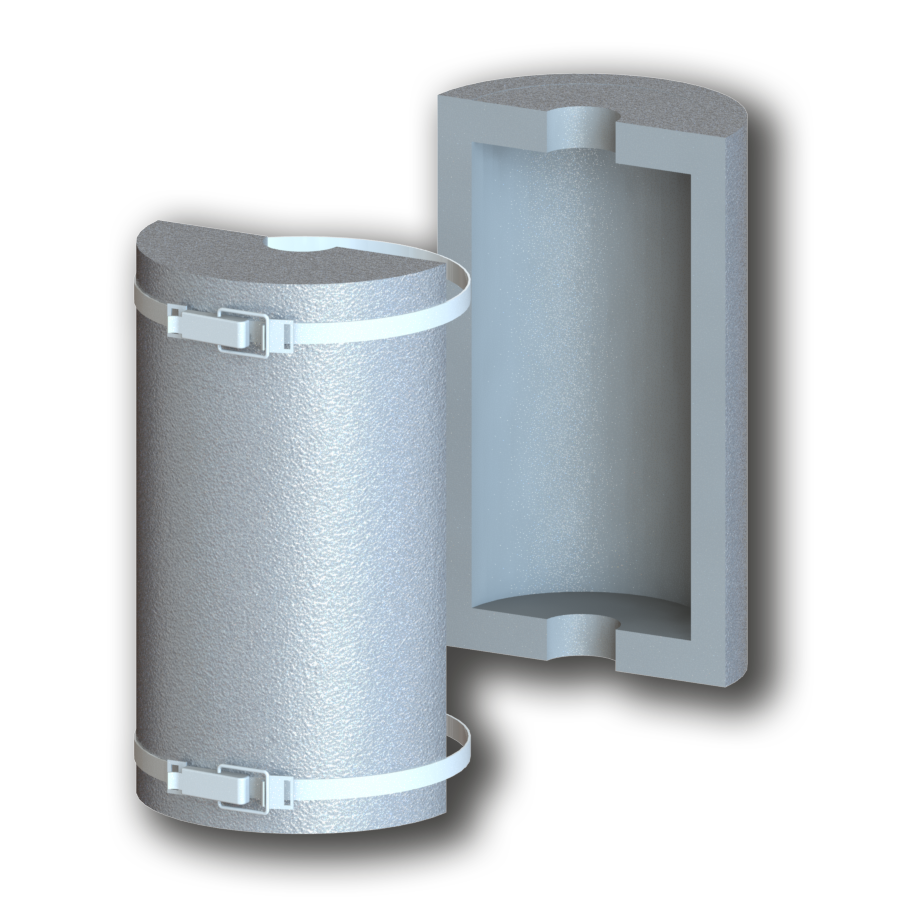

For district and local heating and industry

For district and local heating and industry

For district and local heating and industry

Square insulation for rectangular pipes and distribution beams in station and plant construction

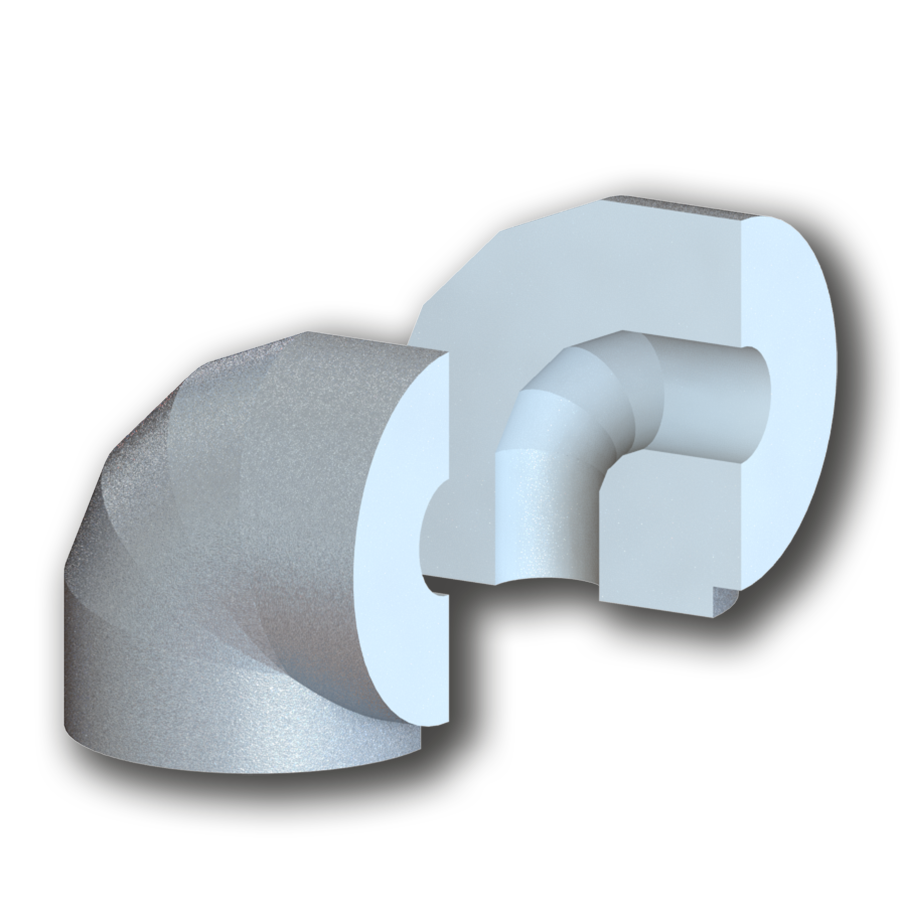

Pipe bend insulation for district and local heating and industry

Pipe bend insulation for district and local heating and industry

Pipe bend insulation for district and local heating and industry

Plant and station insulation system for district and local heating and industry

Plant and station insulation system for district and local heating and industry

Plant and station insulation system for district and local heating and industry

Plant and station insulation system for district and local heating and industry

Plant and station insulation system for district and local heating and industry

Plant and station insulation system for district and local heating and industry

Plant and station insulation system for district and local heating and industry

| Surface | Aluminum coarse grain 0.2mm |

| PU foam | PIR polyisocyanurate rigid foam |

| Fire protection class | B2 according to DIN 4102 |

| Spec. Volume weight | 50 – 80 kg/m3 |

| Thermal conductivity | 0.025 W/mK at 10°C according to EN 12667 0.029 W/mK at 40°C according to EN 12667 0.035 W/mK at 10°C according to EN 14308 0.039 W/mK at 40°C according to EN 14308 |

| Temperature application range | up to +150°C (in peaks +170°C) |