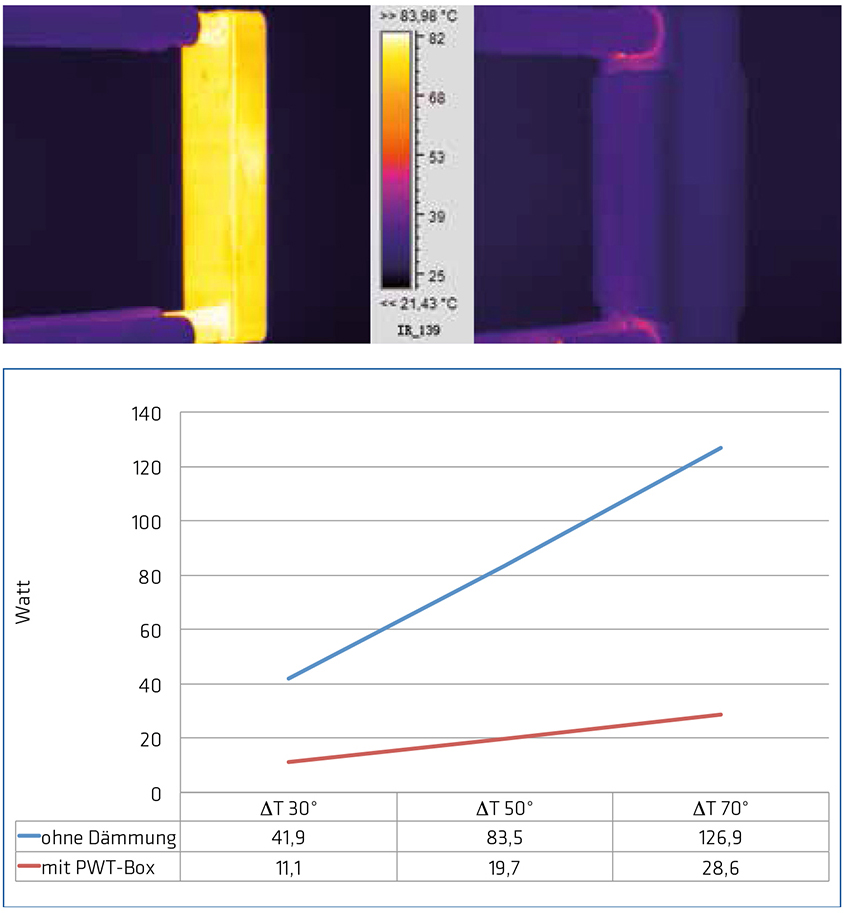

Like every other component of a heating system, the plate heat exchanger component should also be insulated. Plate heat exchangers radiate a lot of heat without insulation due to their large surface area and high operating temperature. Efficient insulation is therefore very important and significantly improves the efficiency of the heating system or district heating transfer station.

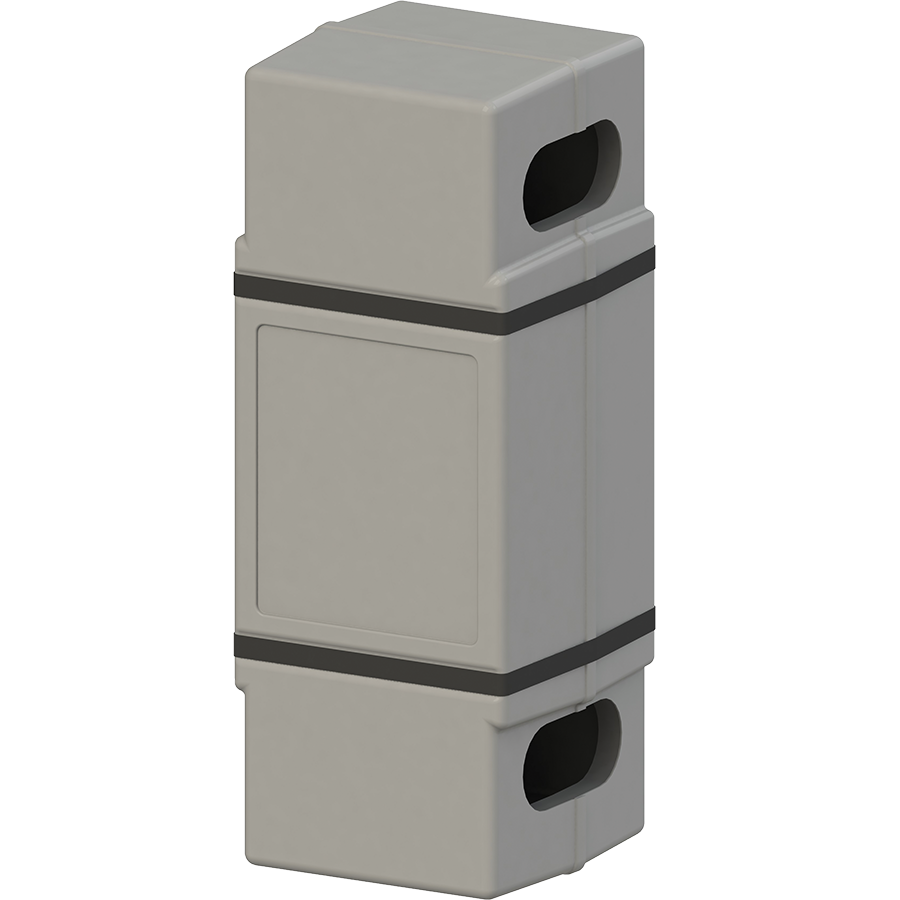

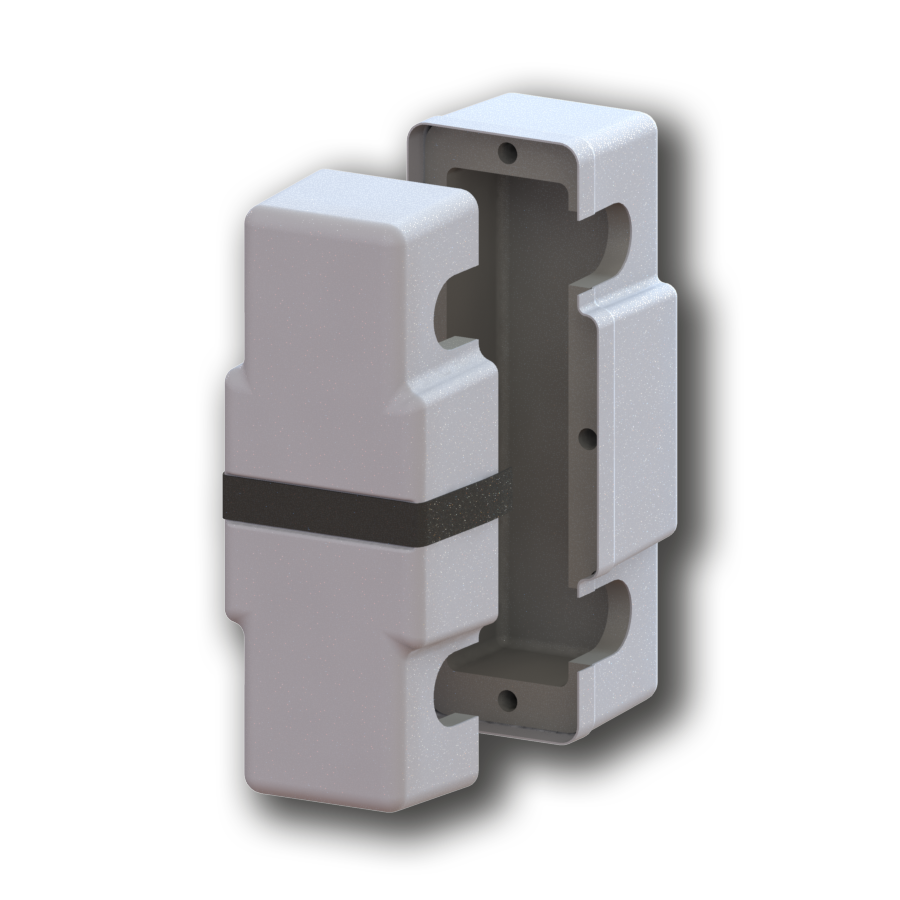

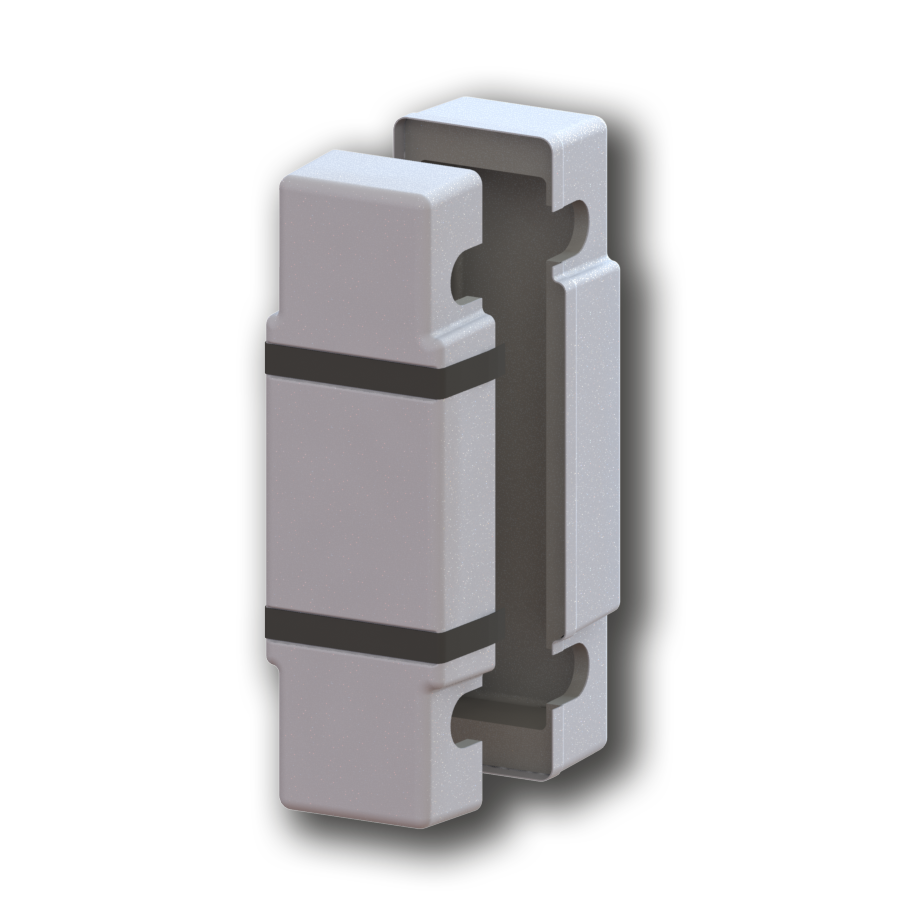

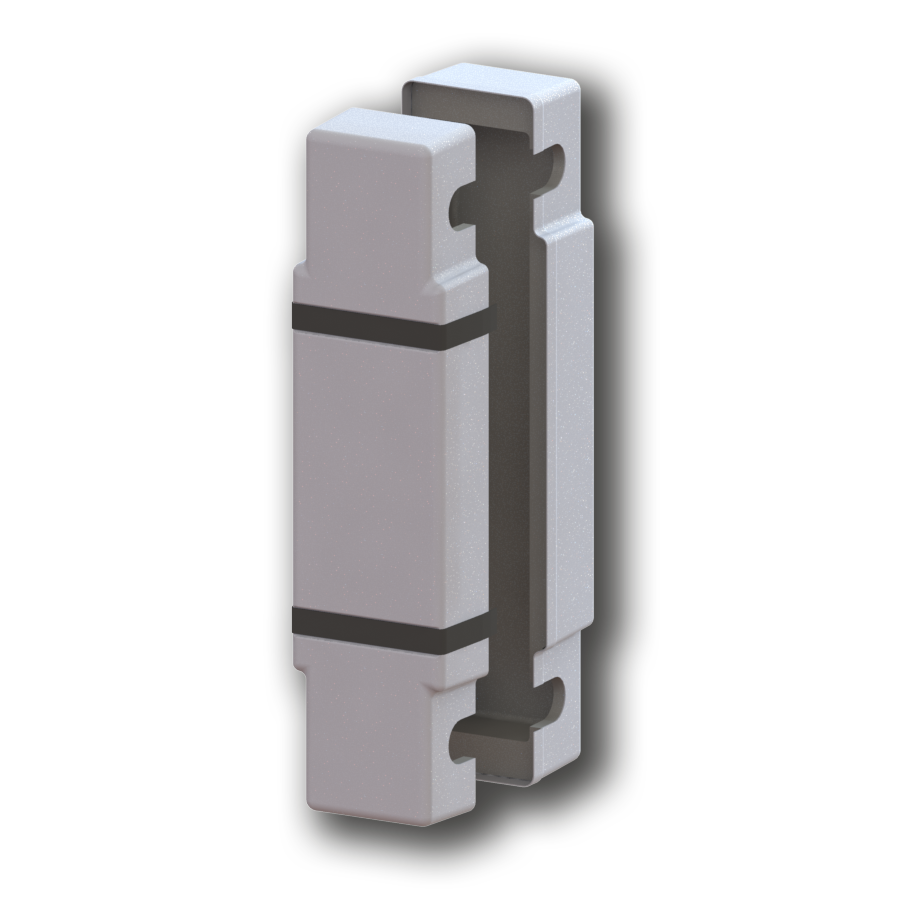

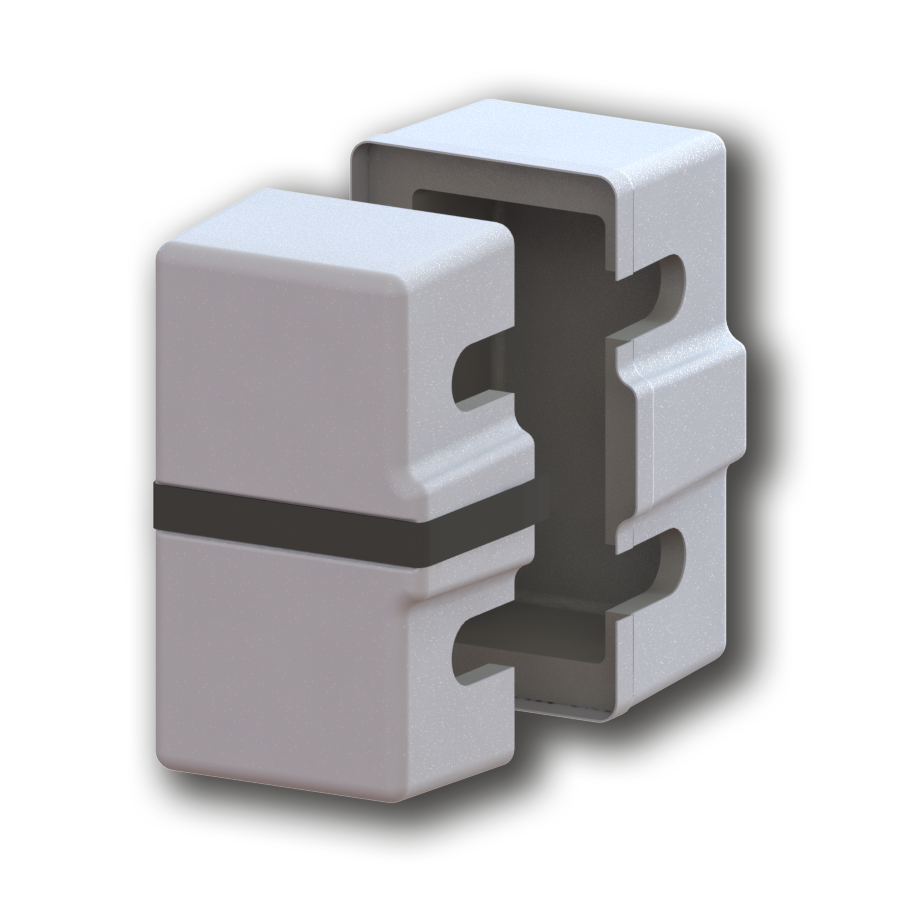

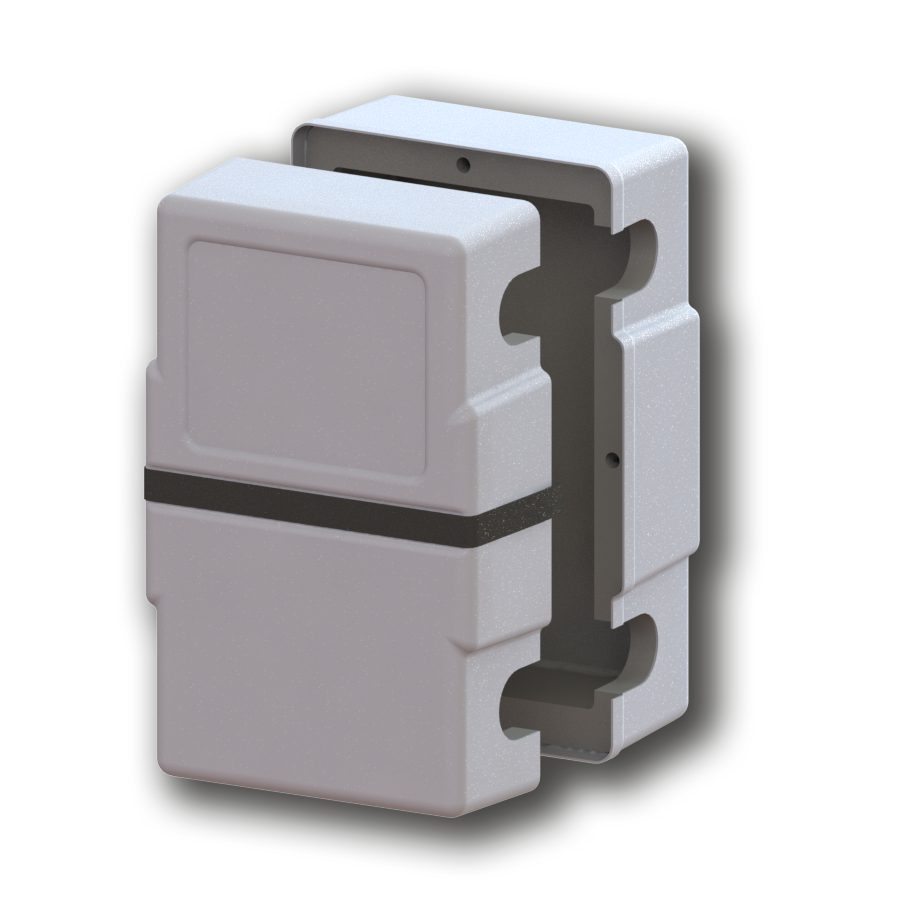

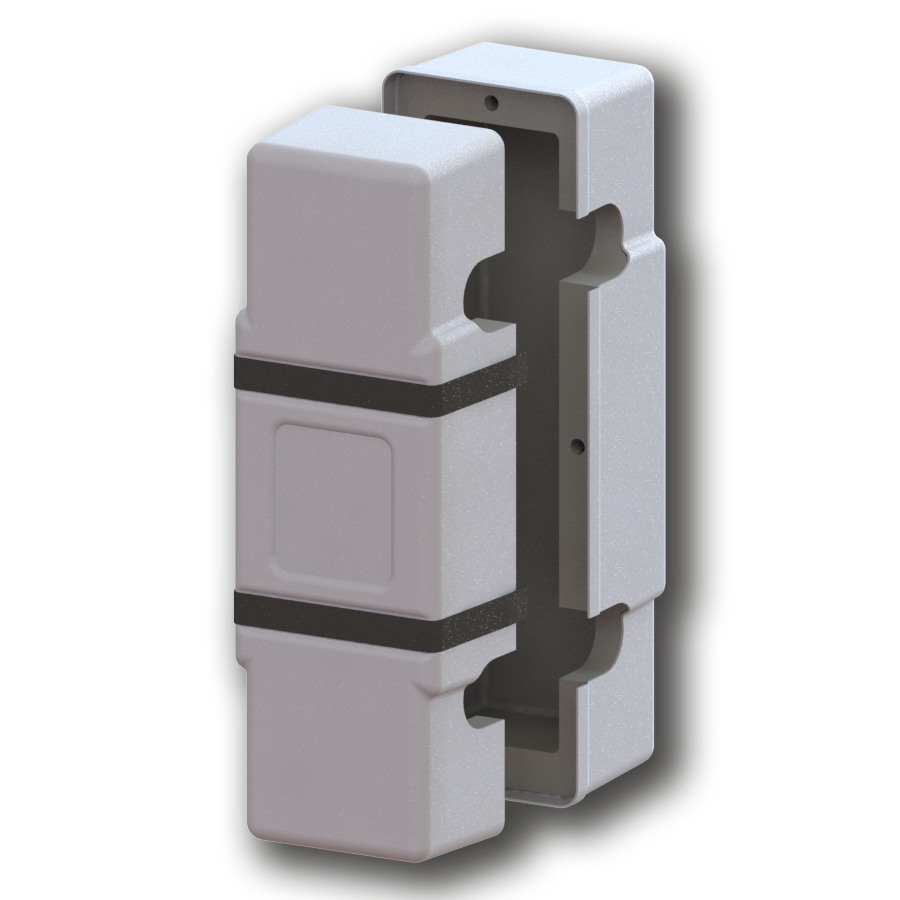

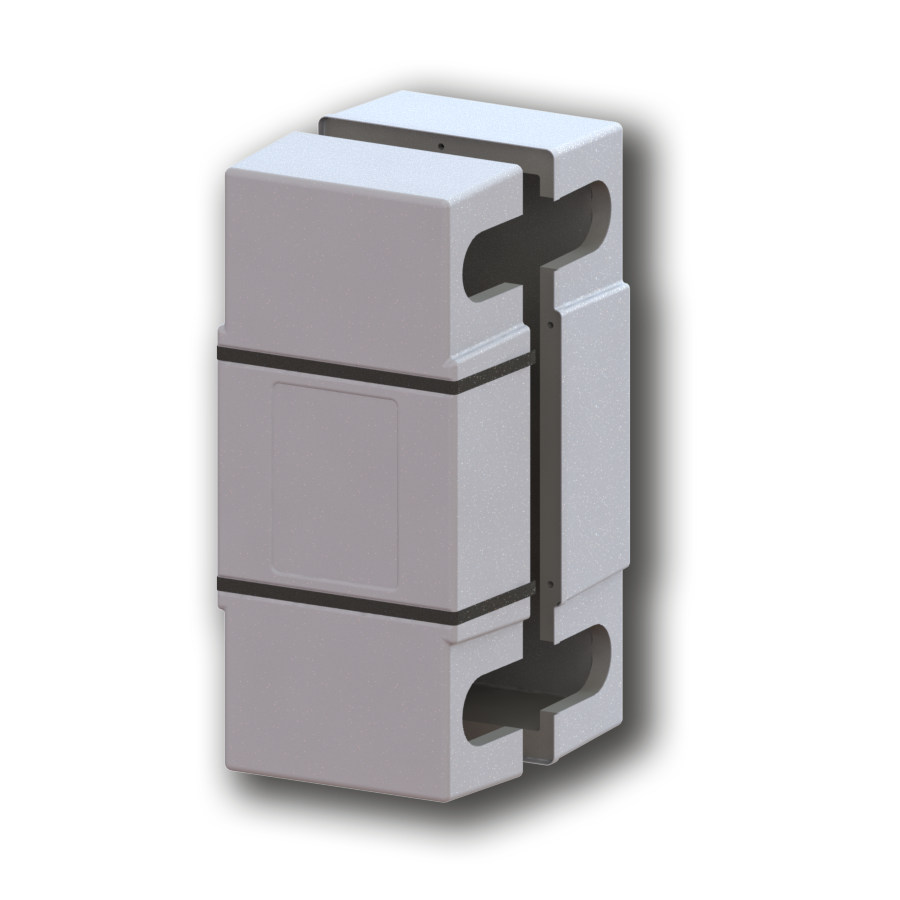

Our standard insulation for plate heat exchangers, the PHE boxes, are characterized by their ease of use and installation. They are reusable, do not need to be glued and allow access to the heat exchanger at any time.

We also offer solutions for heat exchanger insulation in the area of custom-made and individual products:

We would be happy to develop a joint concept with you.

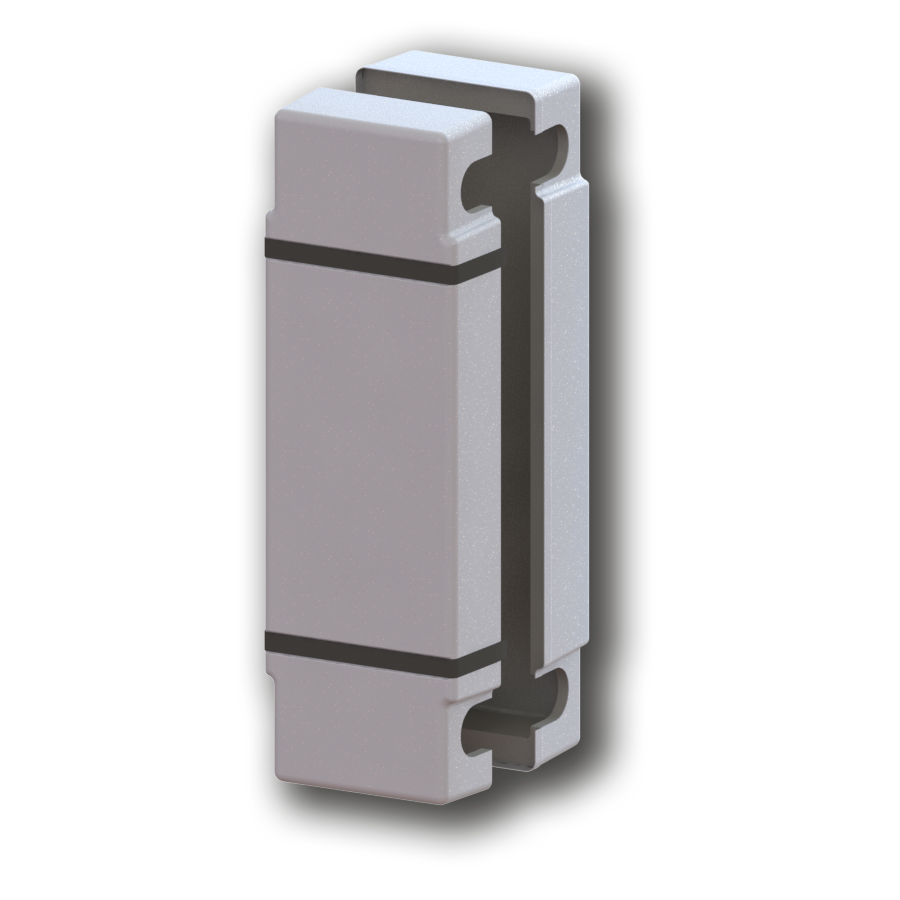

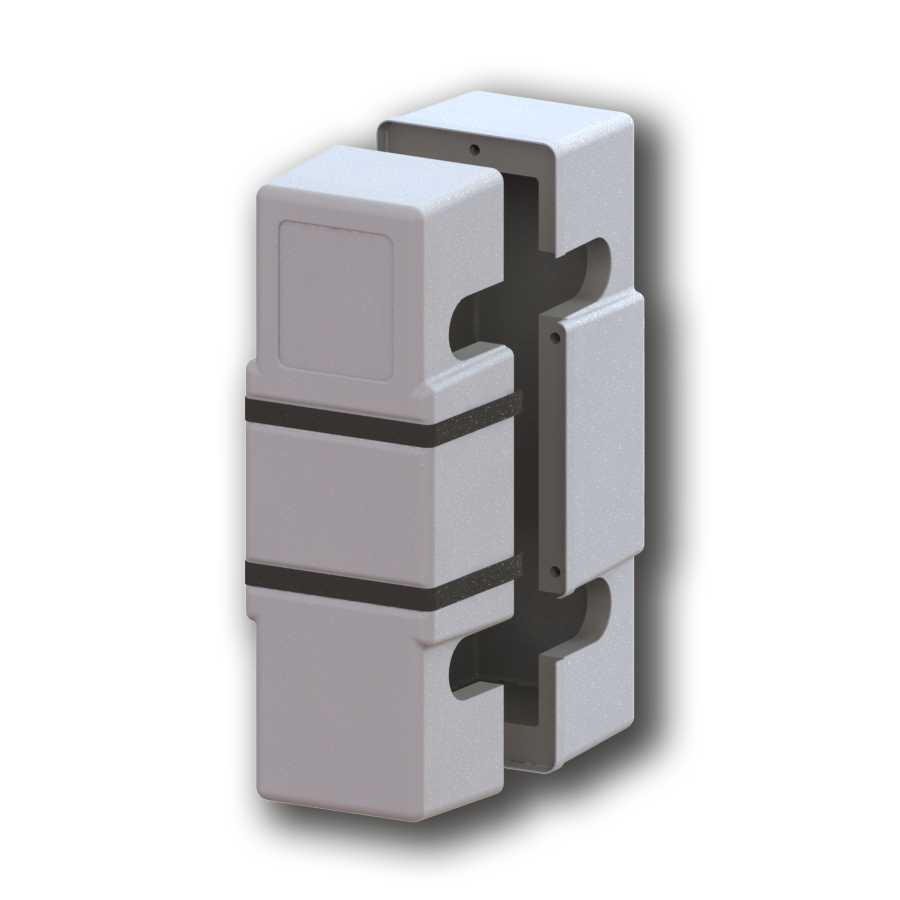

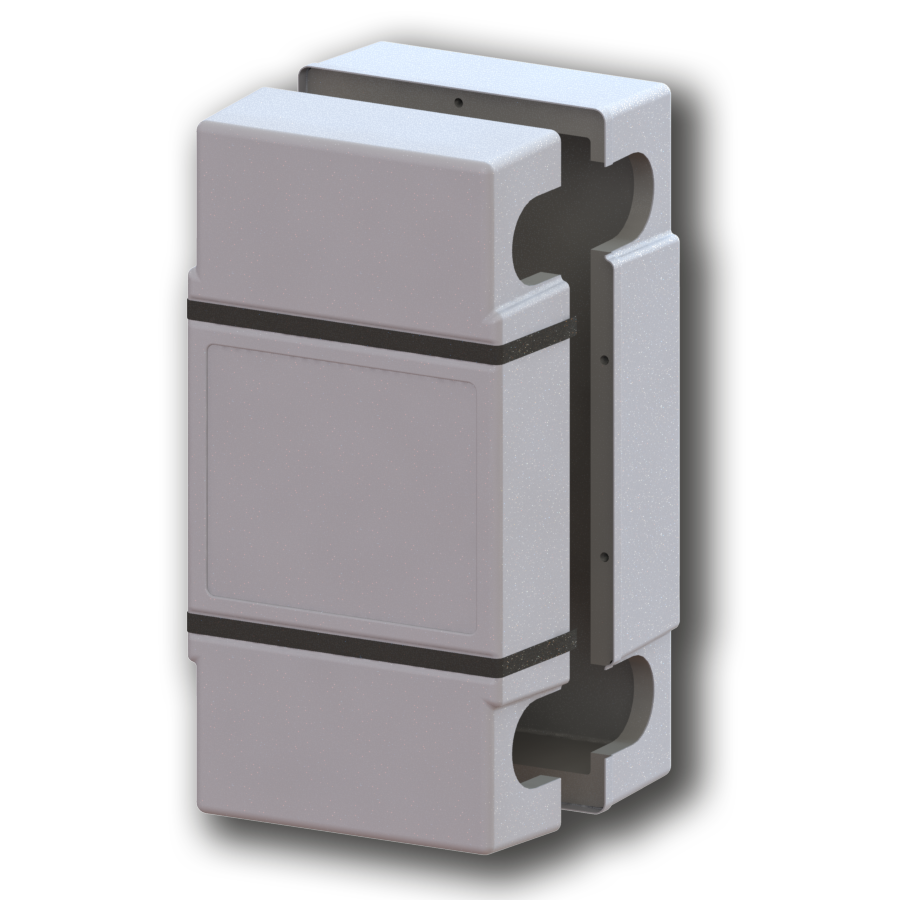

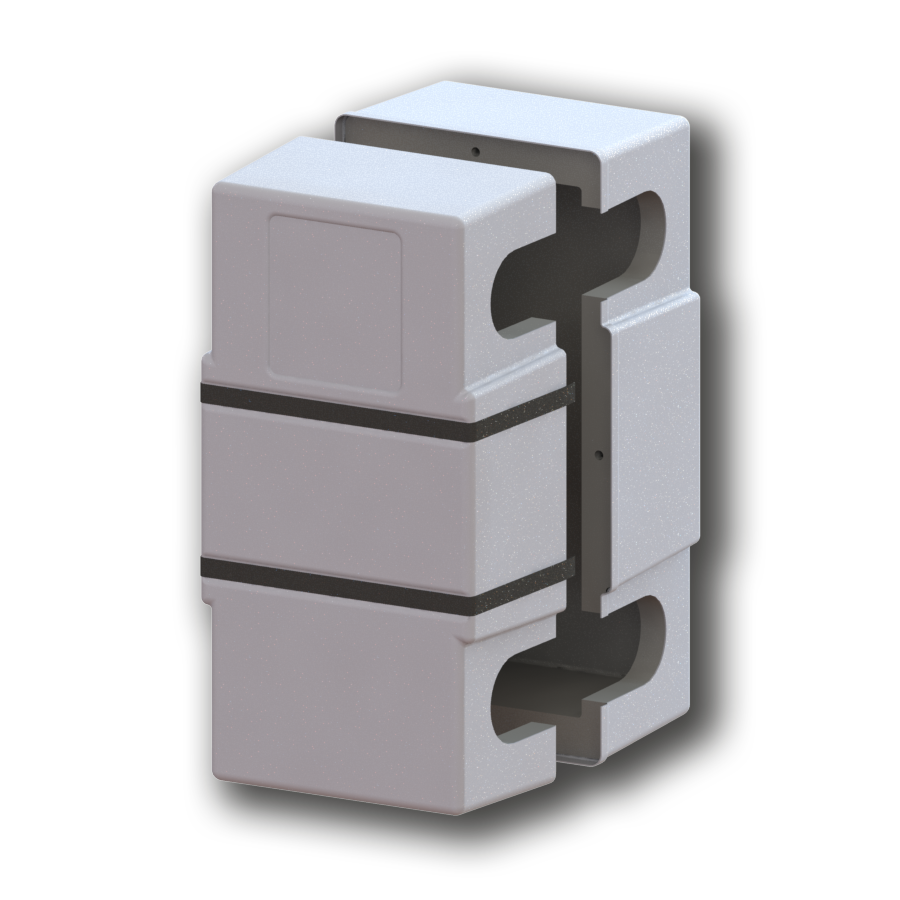

Our standard insulation for brazed plate heat exchangers.

For brazed plate heat exchangers with maximum external dimensions of 90 mm width and 230 mm height. The depth is selected to match the number of plates in the heat exchanger.

For brazed plate heat exchangers with maximum external dimensions of 90 mm width and 315 mm height. The depth is selected to match the number of plates in the heat exchanger.

For brazed plate heat exchangers with maximum external dimensions of 90 mm width and 360 mm height. The depth is selected to match the number of plates in the heat exchanger.

For brazed plate heat exchangers with maximum external dimensions of 90 mm width and 475 mm height. The depth is selected to match the number of plates in the heat exchanger.

For brazed plate heat exchangers with maximum external dimensions of 135 mm width and 185 mm height. The depth is selected to match the number of plates in the heat exchanger.

For brazed plate heat exchangers with maximum external dimensions of 135 mm width and 315 mm height. The depth is selected to match the number of plates in the heat exchanger.

For brazed plate heat exchangers with maximum external dimensions of 135 mm width and 385 mm height. The depth is selected to match the number of plates in the heat exchanger.

For brazed plate heat exchangers with maximum external dimensions of 135 mm width and 545 mm height. The depth is selected to match the number of plates in the heat exchanger.

For brazed plate heat exchangers with maximum external dimensions of 135 mm width and 650 mm height. The depth is selected to match the number of plates in the heat exchanger.

For brazed plate heat exchangers with maximum external dimensions of 200 mm width and 470 mm height. The depth is selected to match the number of plates in the heat exchanger.

For brazed plate heat exchangers with maximum external dimensions of 200 mm width and 650 mm height. The depth is selected to match the number of plates in the heat exchanger.

For brazed plate heat exchangers with maximum external dimensions of 280 mm width and 545 mm height. The depth is selected to match the number of plates in the heat exchanger.

For brazed plate heat exchangers with maximum external dimensions of 325 mm width and 820 mm height. The depth is selected to match the number of plates in the heat exchanger.

| Material | Polystyrene PS (no PVC) |

| Fire protection class | B1 according to DIN 4102 |

| Color | gray RAL7040 |

| Strength | 0.8mm to 3mm |

| Impact strength | 50kJ/m3 at 23°C |

| Material | Rigid polyurethane foam |

| Fire protection class | B2 according to DIN 4102 and E according to EN 13501-1 |

| spec. Volume weight | 55 – 60 kg/m3 |

| Thermal conductivity | 0.022 W/mK at 10°C according to EN 12667 0.025 W/mK at 40°C according to EN 12667 0.029 W/mK at 10°C according to EN 14308 0.032 W/mK at 40°C according to EN 14308 |

| Application | Heat up to +130°C |